Technical Sheet

| Model

|

CCVS 260 T |

| Frequency

|

60 Hz |

| Standard Power

|

1,000 W

|

| Nominal Current |

1 A

|

| Peak Current

|

4.5 A |

| Maximum Vacuum Pressure |

0.1 MPa

|

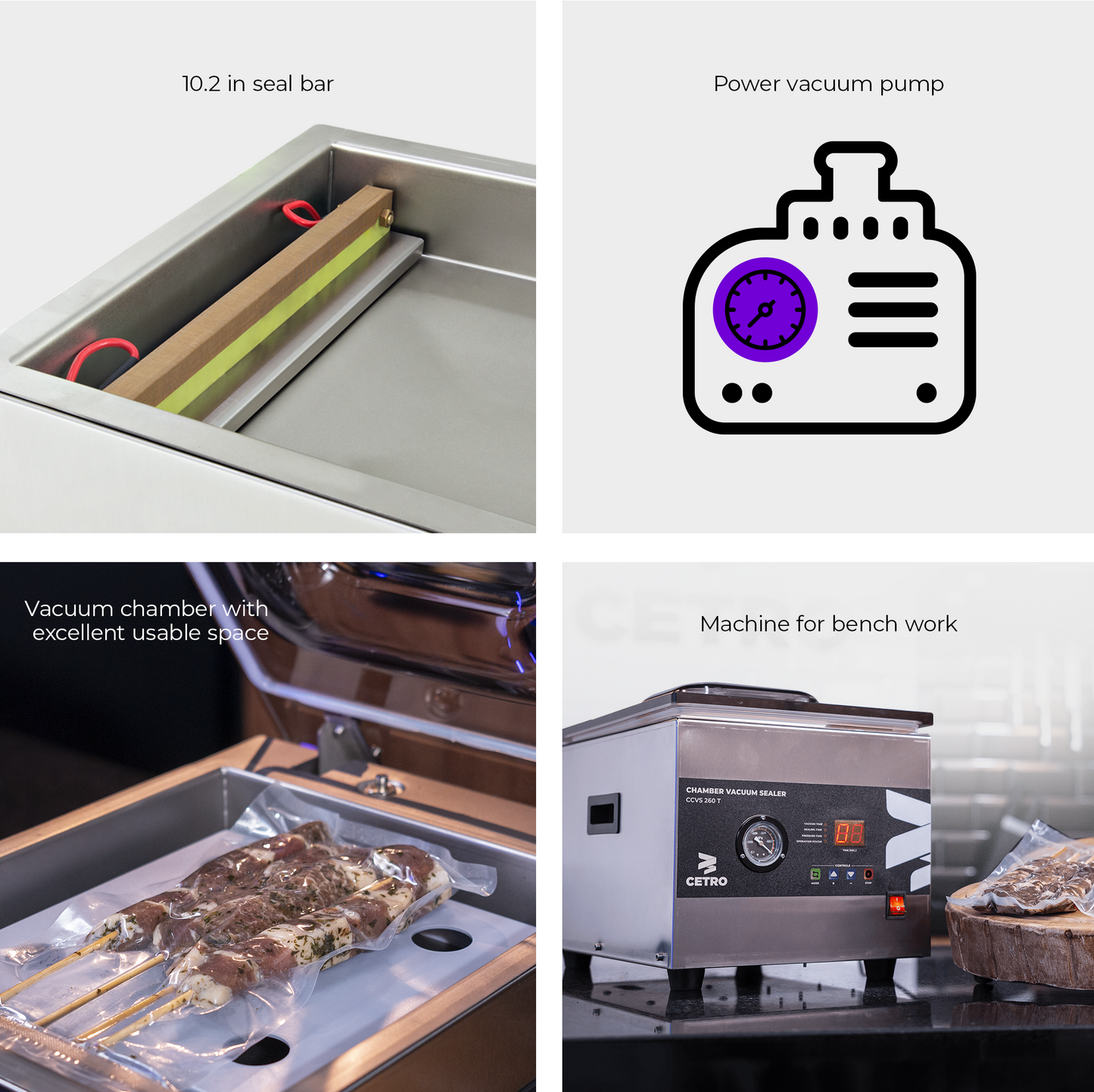

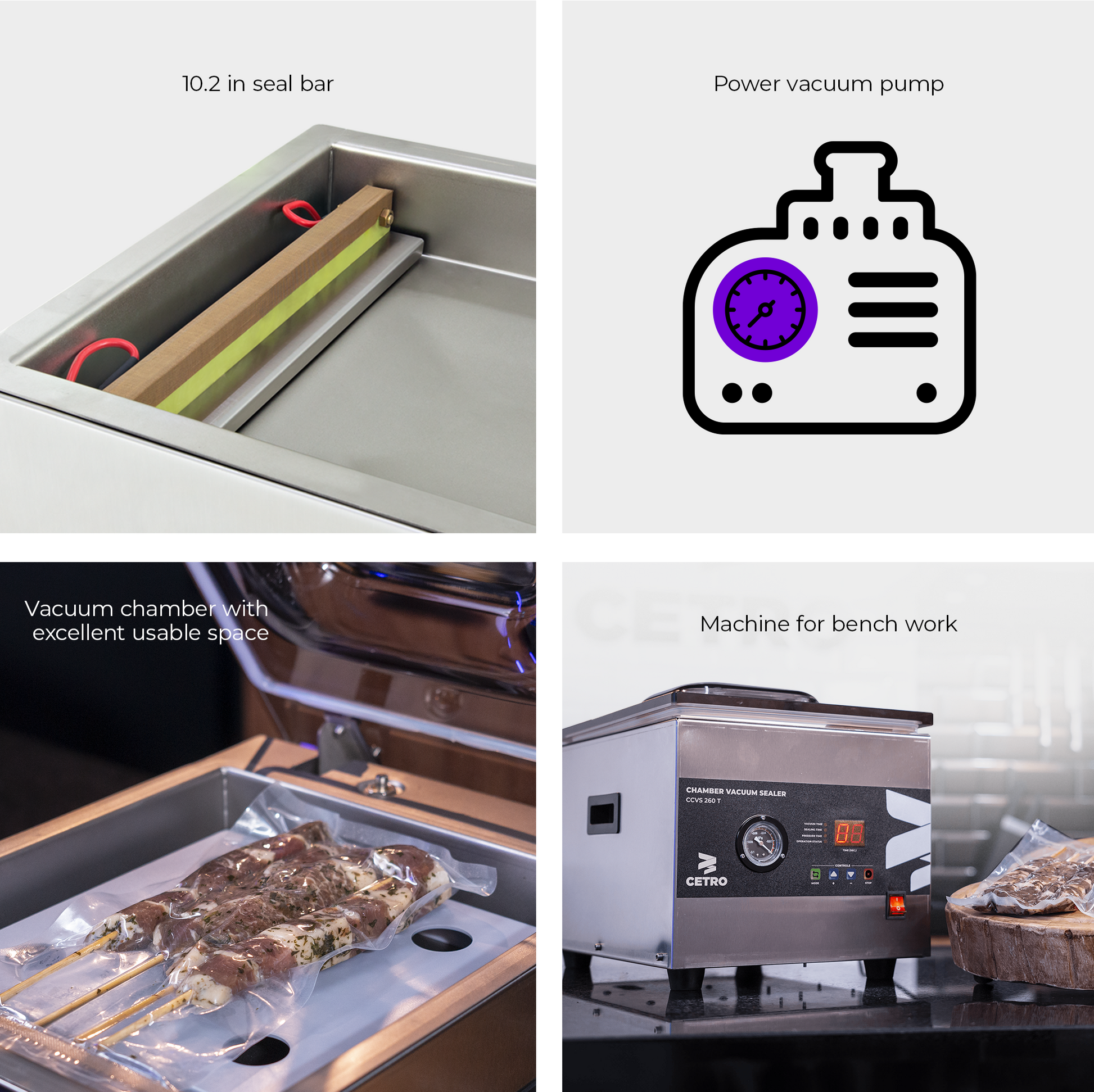

| Heat-sealing bar dimensions (L x W) |

10.2 x 0.3 inches |

| Chamber dimensions (L x W x H) |

10.6 x 12.6 x 2.2 inches |

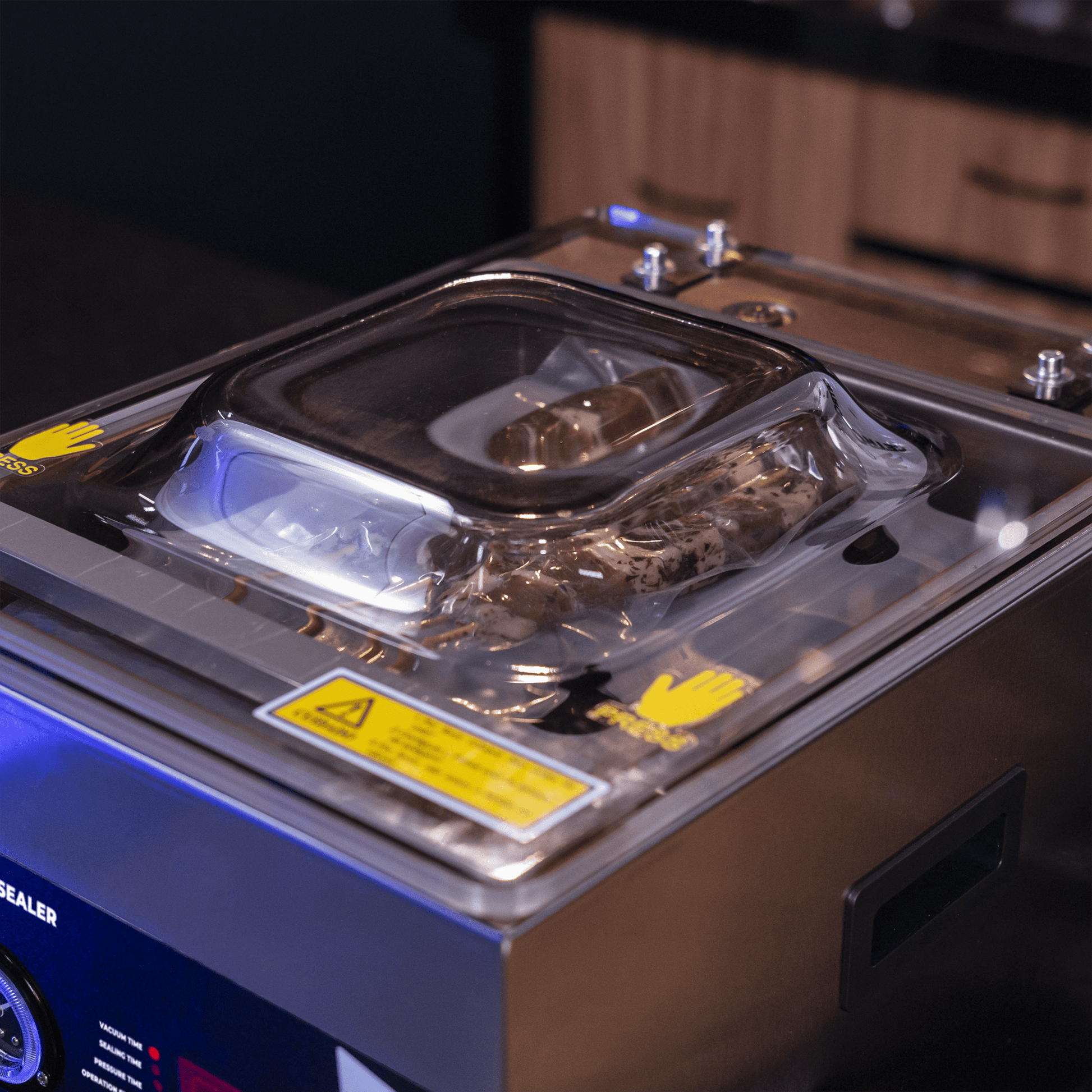

| Machine dimensions (L x W x H) |

19.7 x 15.7 x 15.4 inches |

| Weight |

21.5 kg

|

About the product

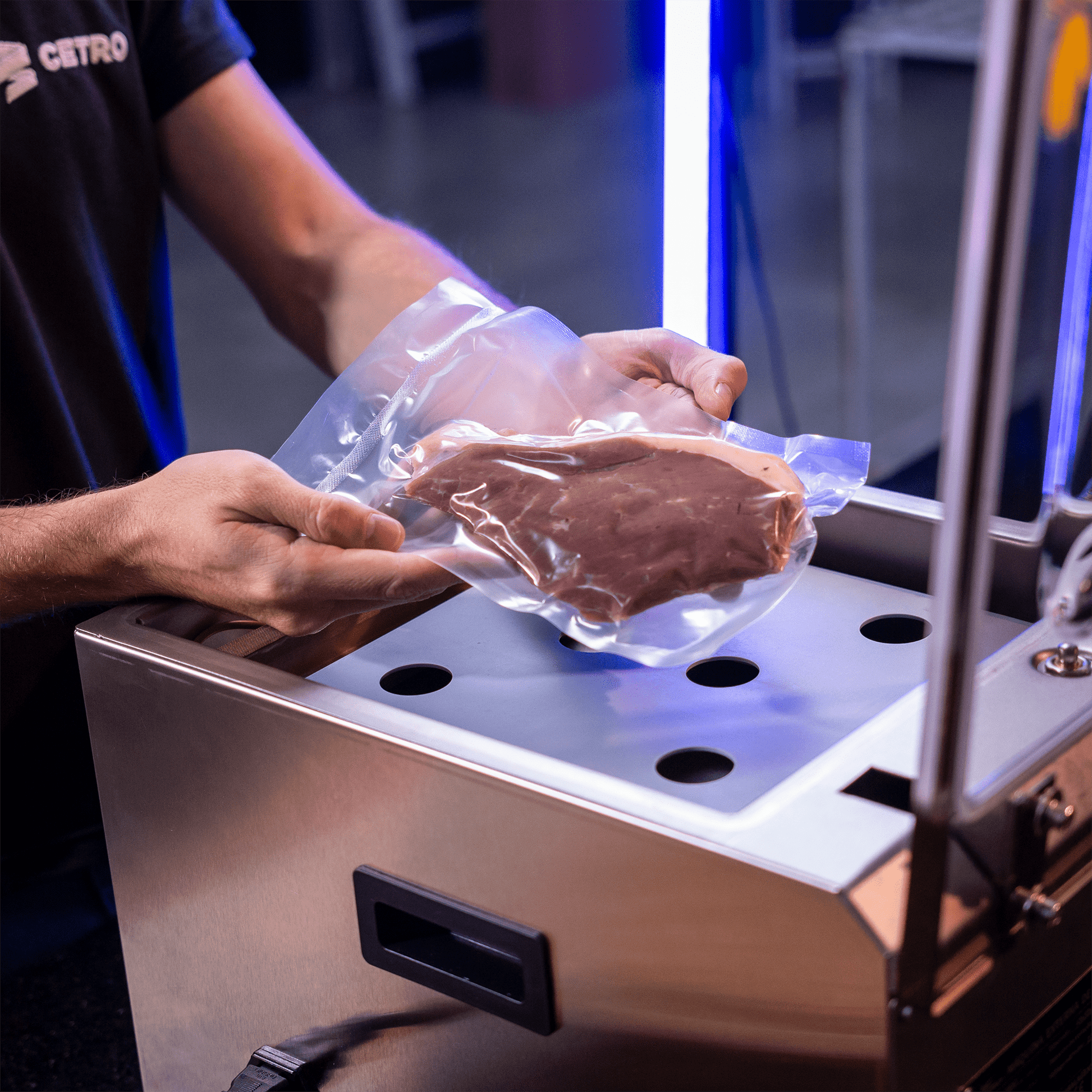

Cetro Chamber Vacuum Sealer CCVS 260 T

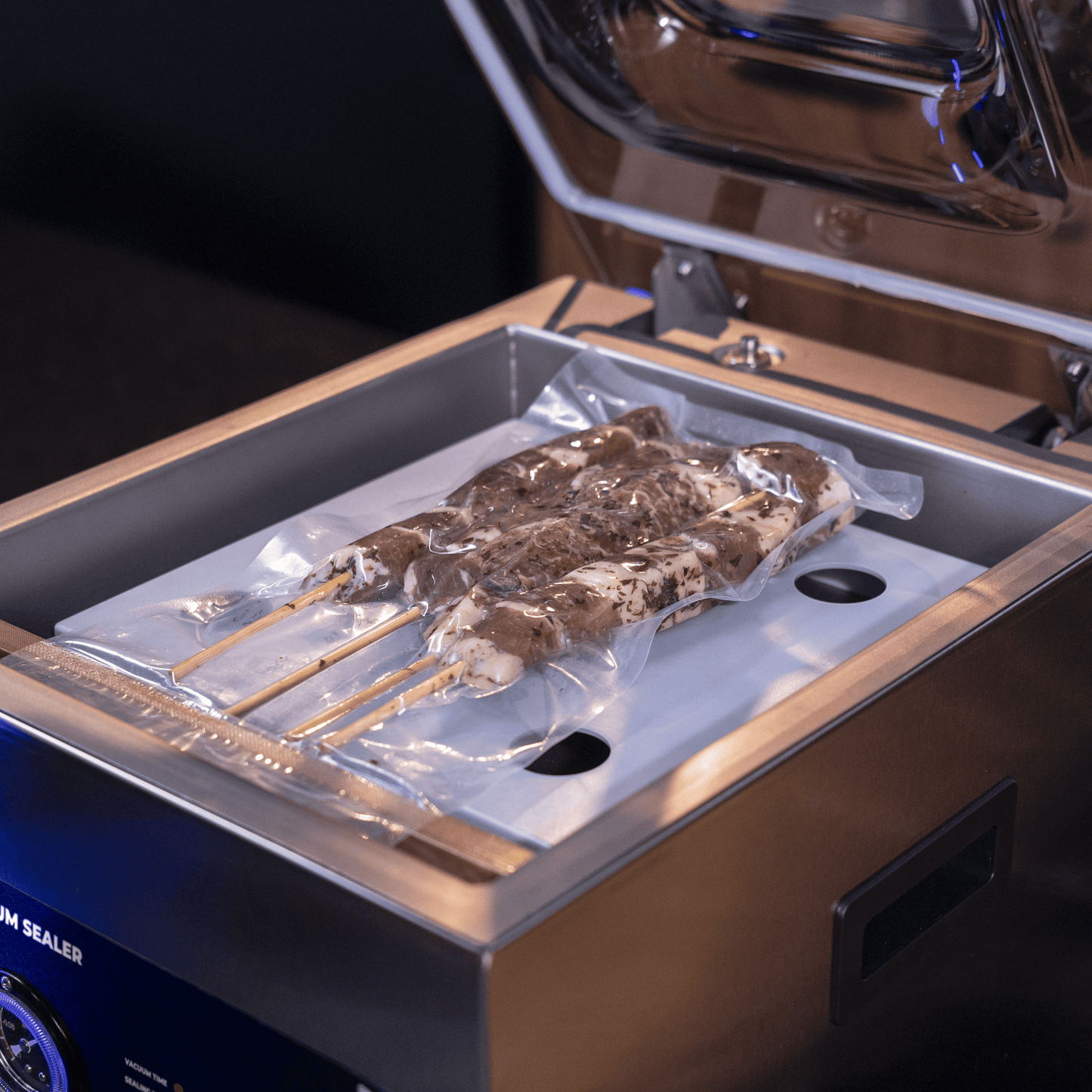

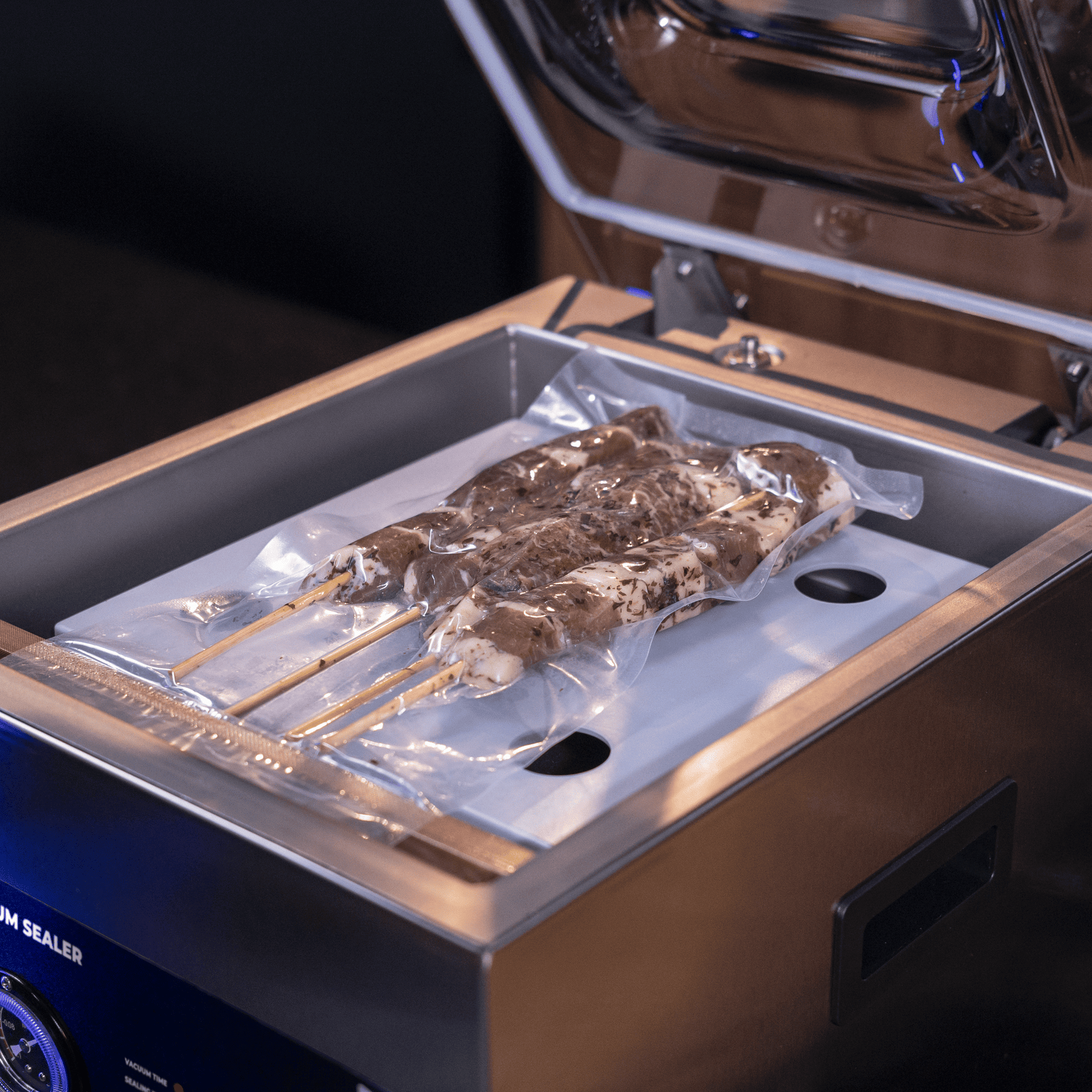

Cetro Chamber Vacuum Sealer CCVS 260 T is a compact, robust, and powerful tabletop machine that speeds up production and seals liquid products. It is an efficient machine with adjustments of sealing time and temperature, vacuum time, a powerful vacuum pump, and a large acrylic lid.

Its panel is digital and has easy settings according to the product and the thickness of the vacuum bag, such as sealing time and temperature, as well as vacuum time and pressure. Thus, CCVS 260 T can be perfectly adapted to the specific shapes and needs of different production lines.

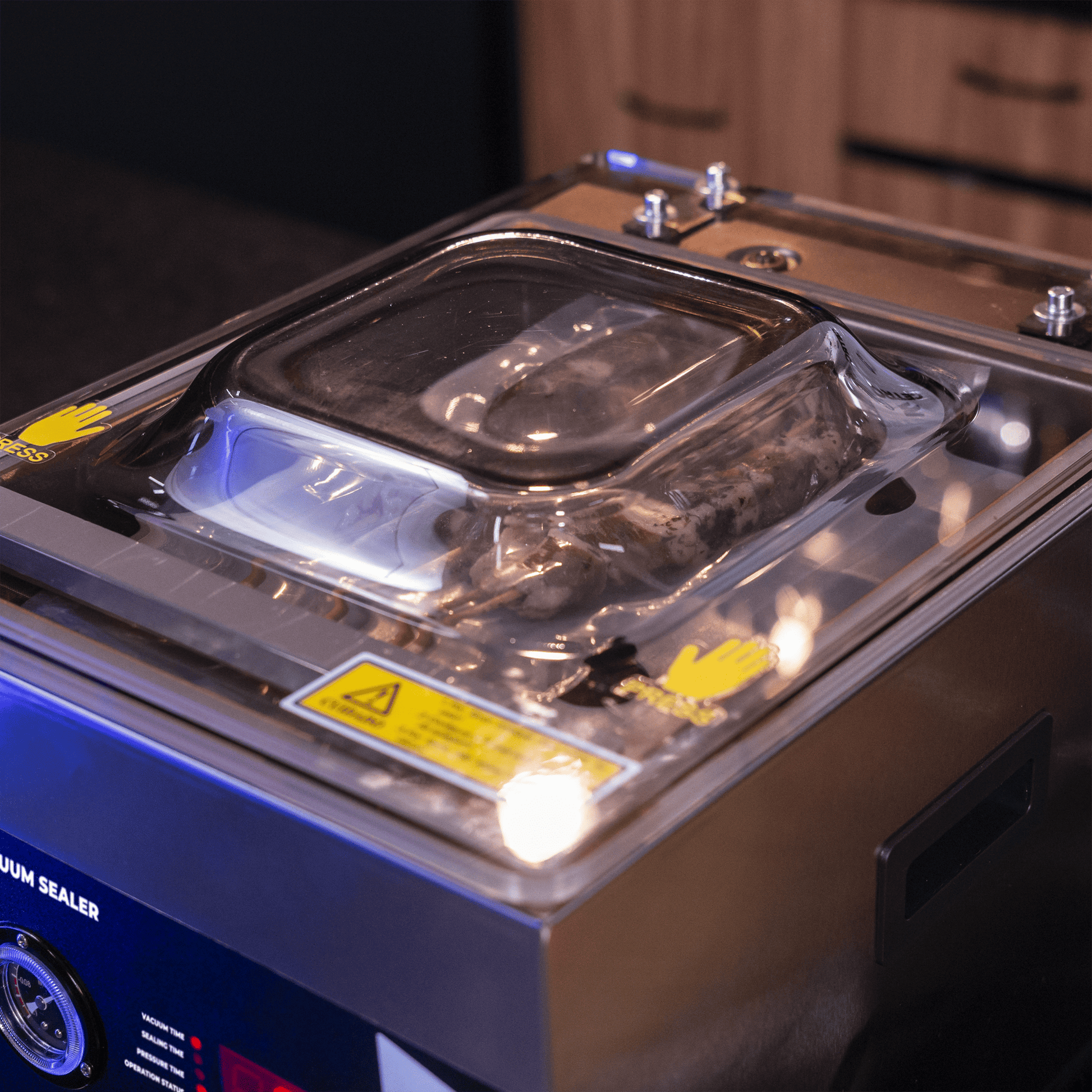

DIVERSITY OF APPLICATIONS

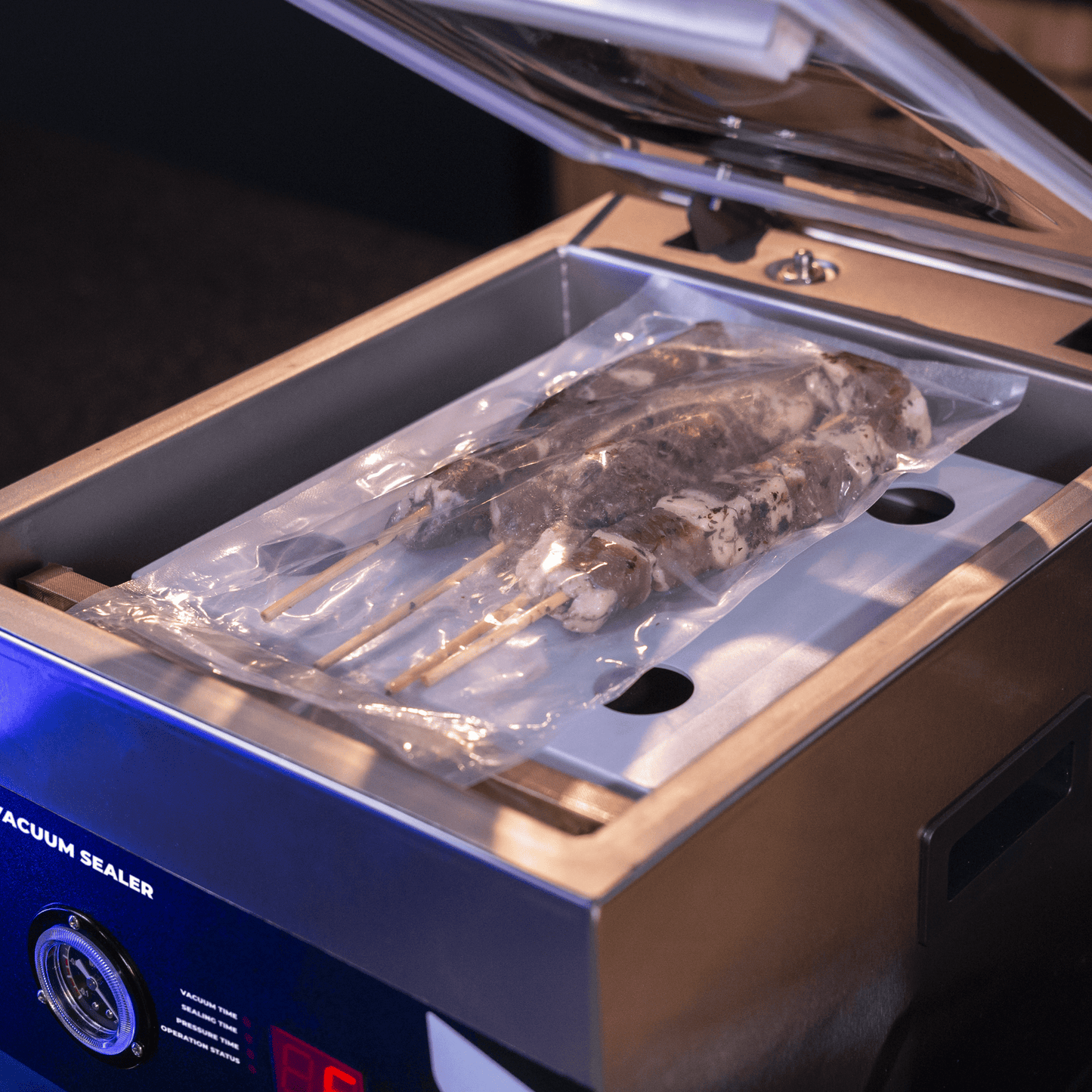

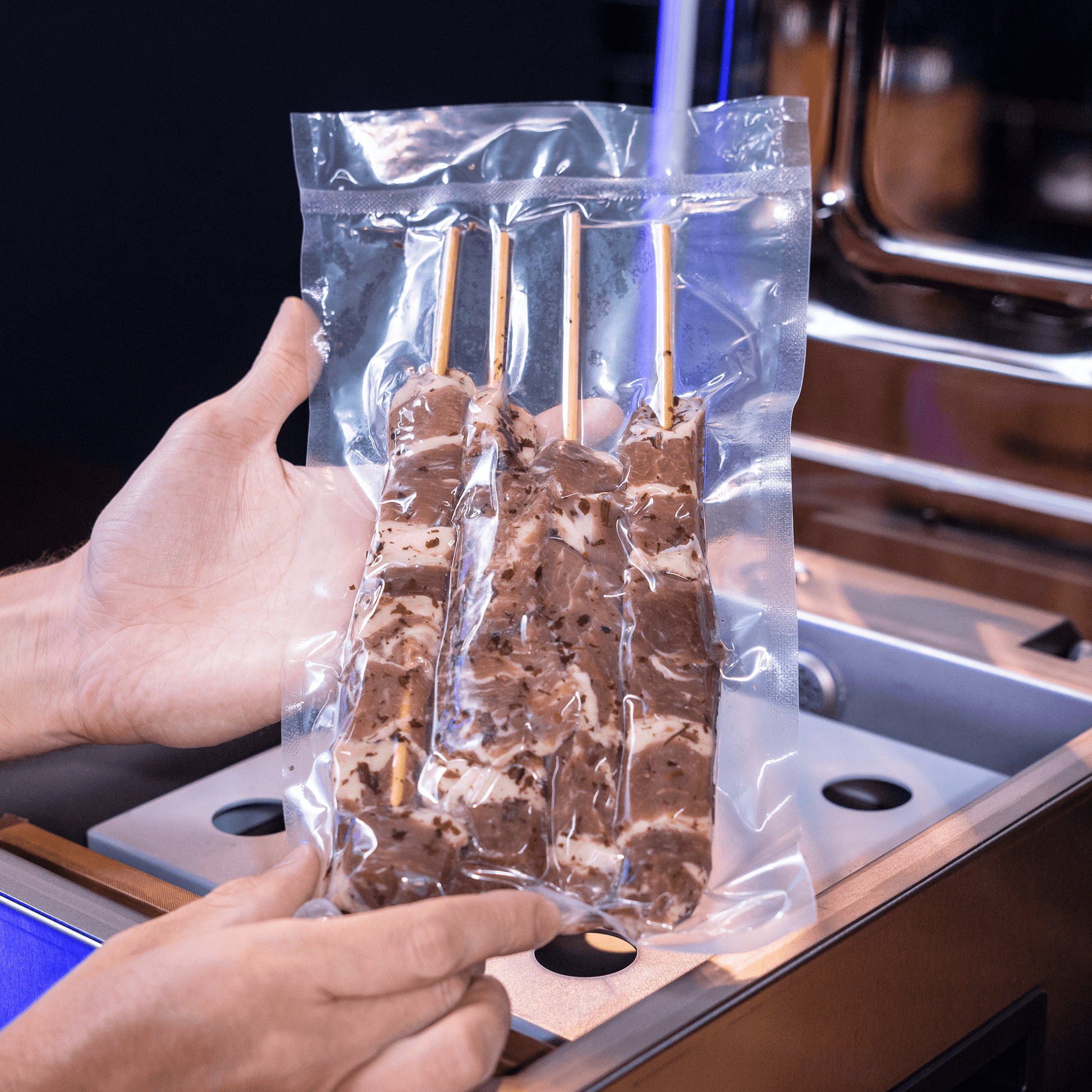

Various segments of industry and commerce use CCVS 260 T to seal packages with meat, snacks, fish, vegetables, cereals, sausages, pizzas, hearts of palm, sliced cold cuts, poultry, pasta, cheese, beef, frozen foods, mushrooms, fruits, and others.

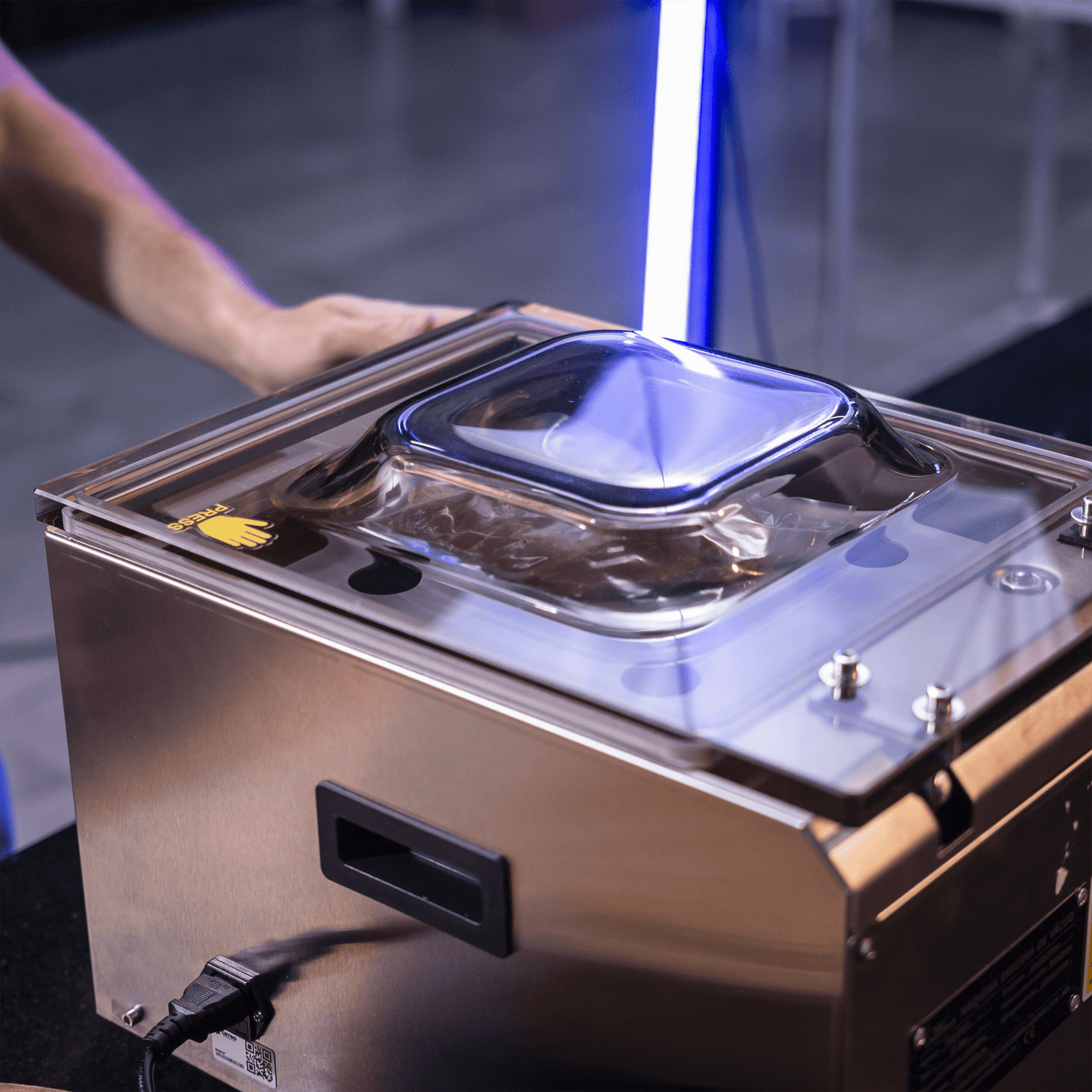

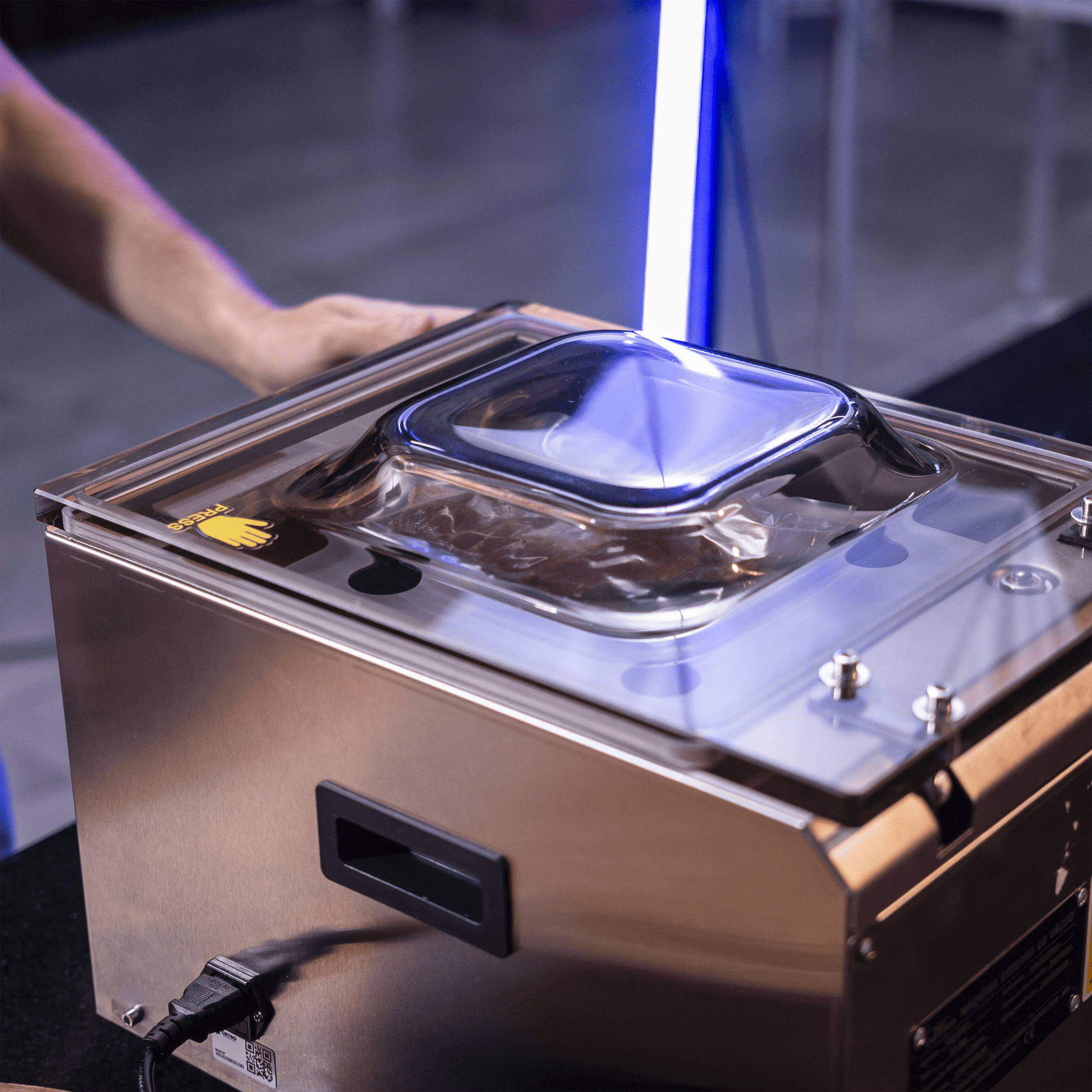

ACRYLIC LID

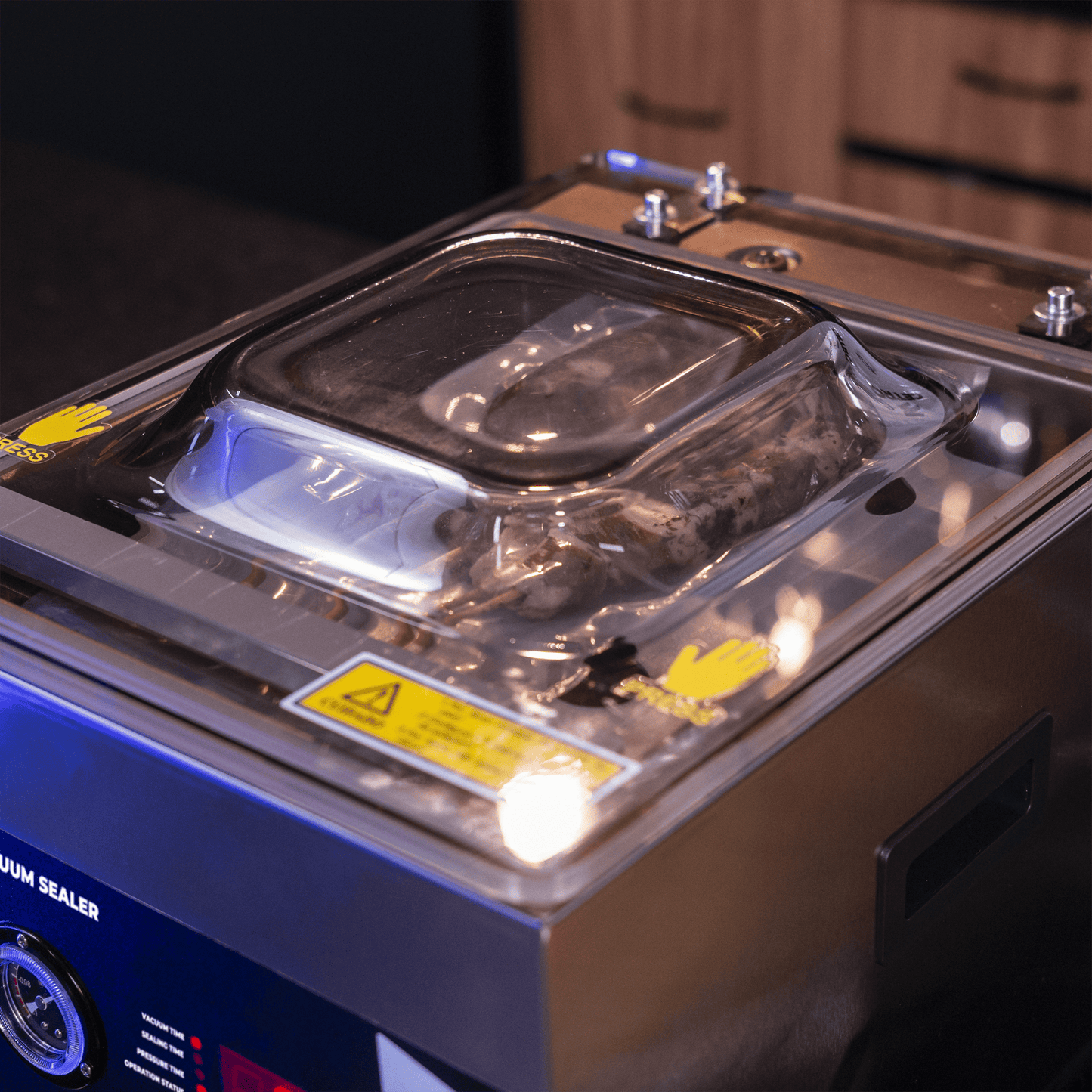

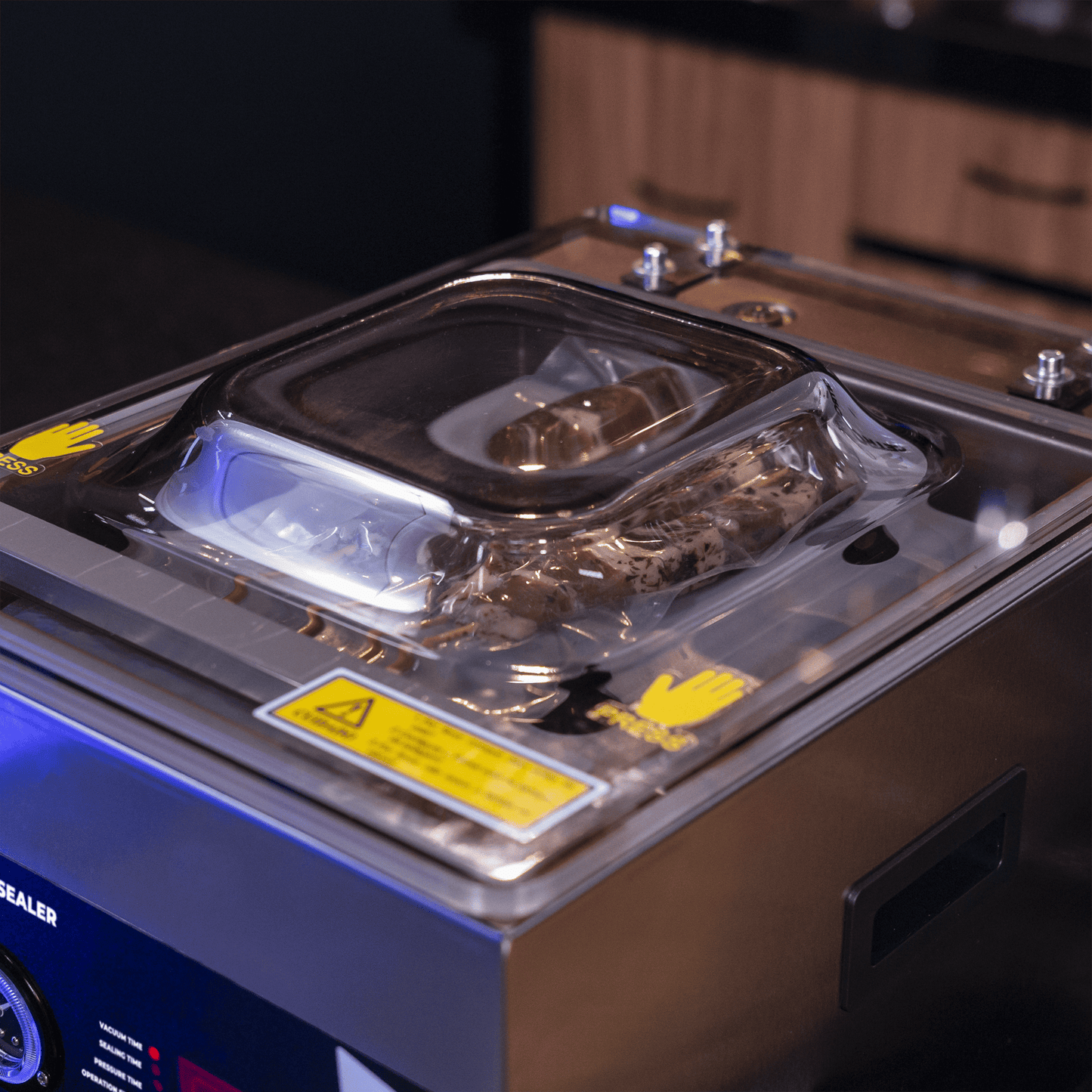

CCVS 260 T has an acrylic lid that allows better visualization of the process and a powerful vacuum pump, which makes the equipment the perfect union between the simplicity of operation, practicality of accommodation, and power.

SIMPLE AND AGILE OPERATION

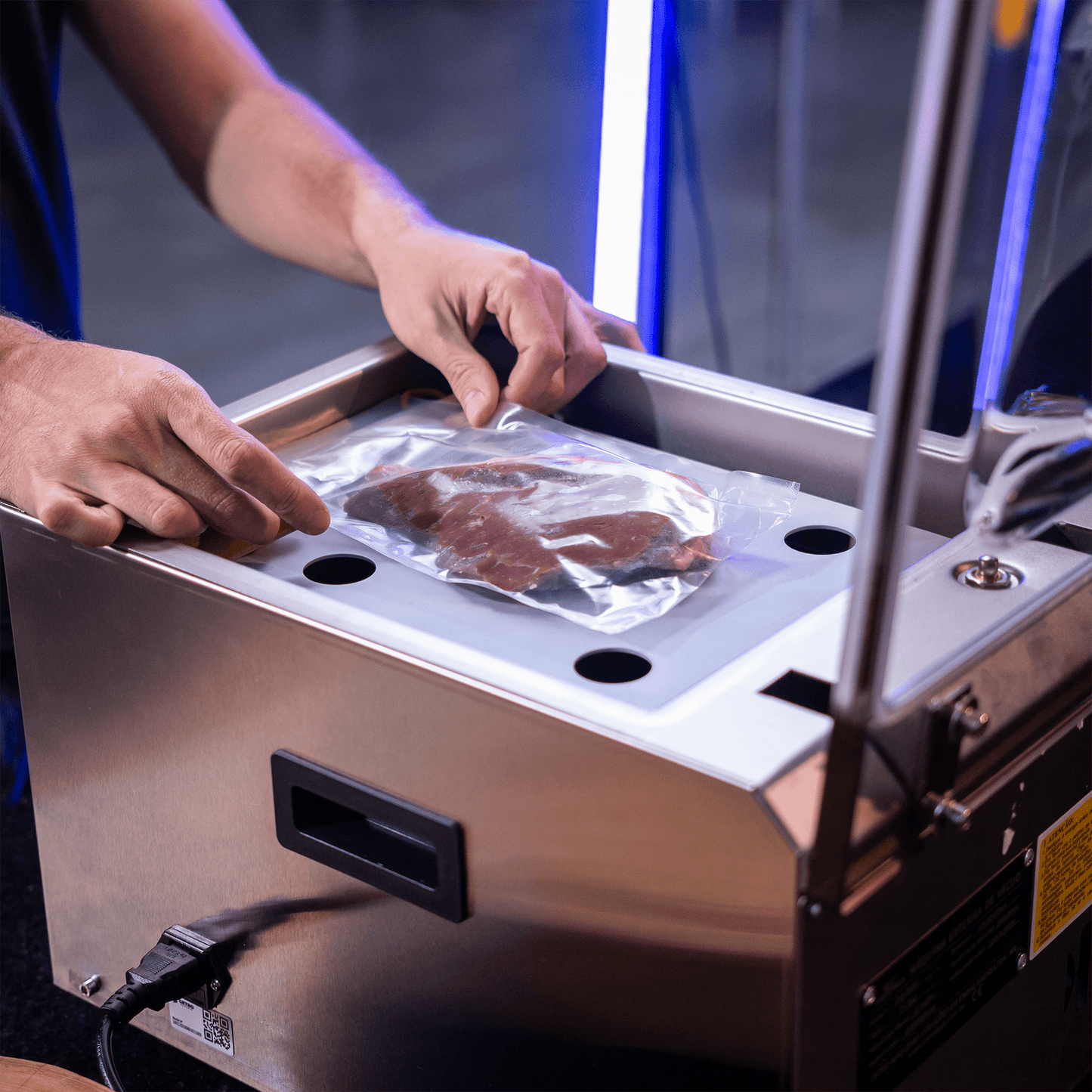

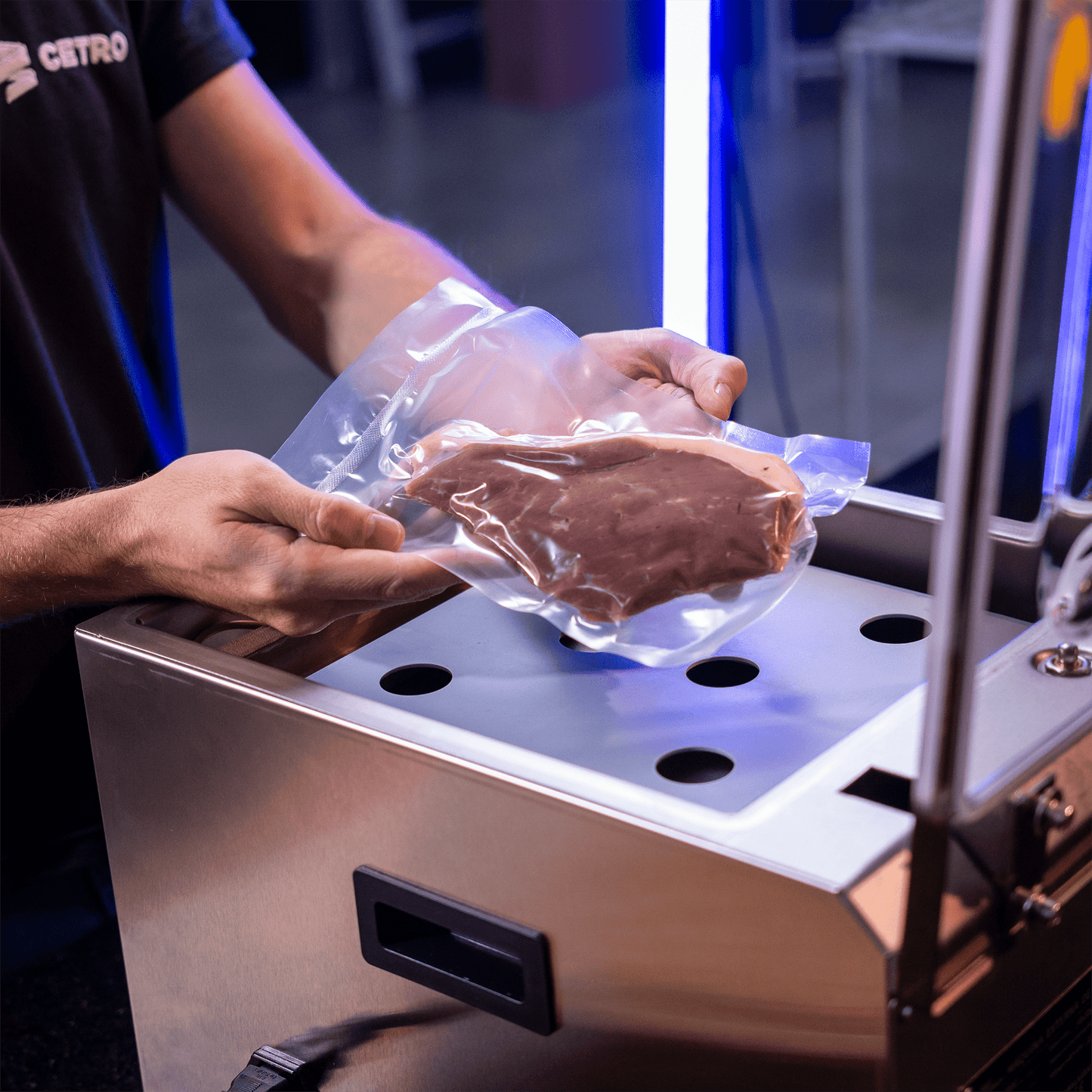

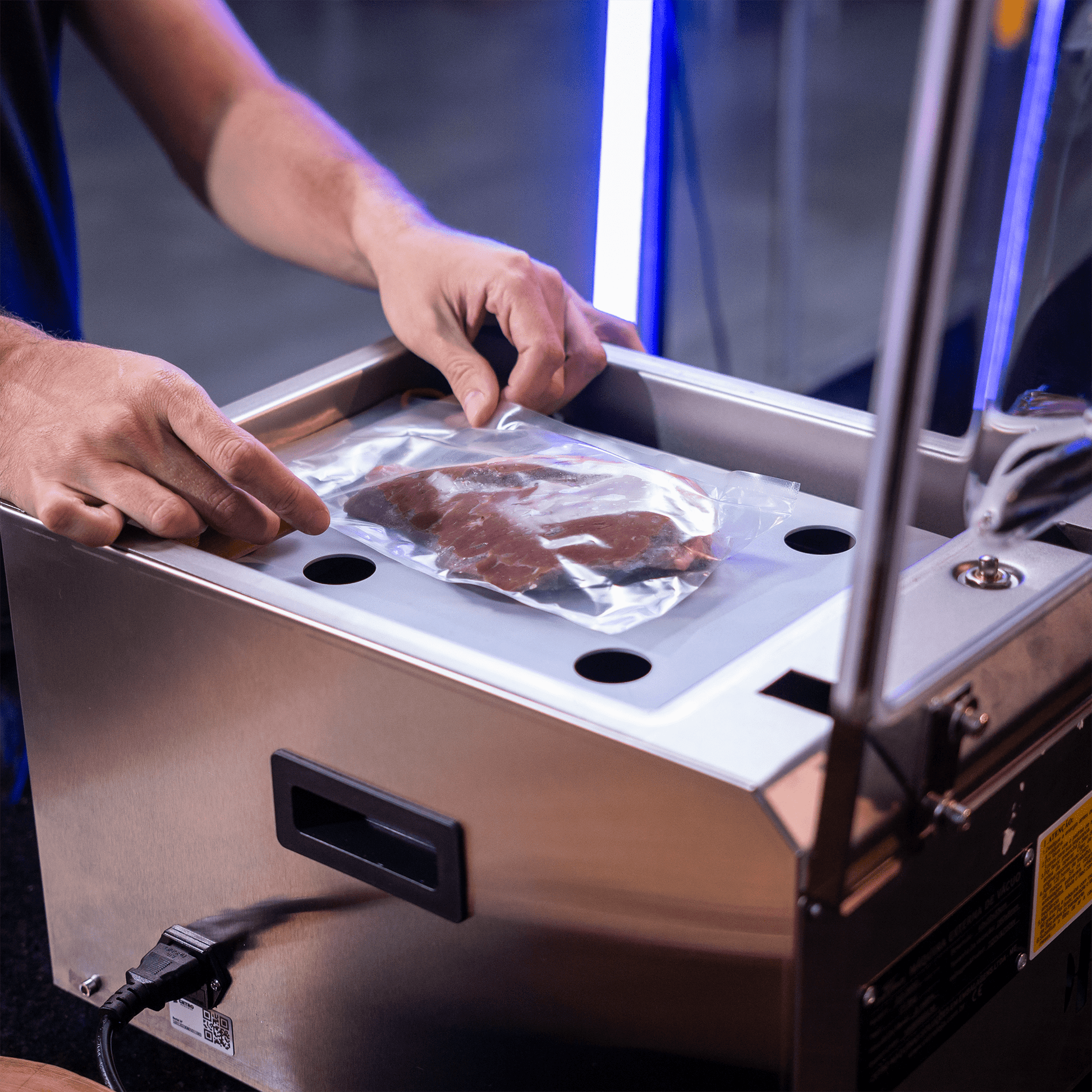

The process is semiautomatic with only the manual placement and removal of the product from the chamber. In addition, it has low energy consumption and a vacuum time that varies from 0 to 60 seconds per cycle, depending on the product. Thus, this equipment maintains excellent productivity and cost-effectiveness.

ADVANTAGES OF VACUUM PACKAGING

Vacuum packing is the best solution for your business, for products sold directly to the customer or for domestic use. In the vacuum packaging process, the products are sealed inside plastic bags with total removal of the air, to prevent the growth of microorganisms such as fungi, bacteria, and microbes. This decelerates food spoilage and prevents further oxidation and natural enzymatic actions.

Need Help?

Click here to speak to a sales representative now or call +1 (800) 917-0511 and ask all your questions.

Easy Payment

Easy Payment Consulting with Experts

Consulting with Experts Secure Purchase

Secure Purchase