Technical Sheet

| Model

|

CCVS 686 3SB T

|

| Standard power

|

2,355 W

|

| Frequency |

60 Hz

|

| Type of Vacuum Pump

|

Oil Pump

|

| Noise Emission

|

73.9 dB

|

| Vibration Level

|

0.34 m/s² |

| Pressure

|

-29.9 inHg (-102 mbar) direct from the pump, -29,5 inHg (-1000 mbar) in the vacuum chamber

|

| Heat-resistant Tape

|

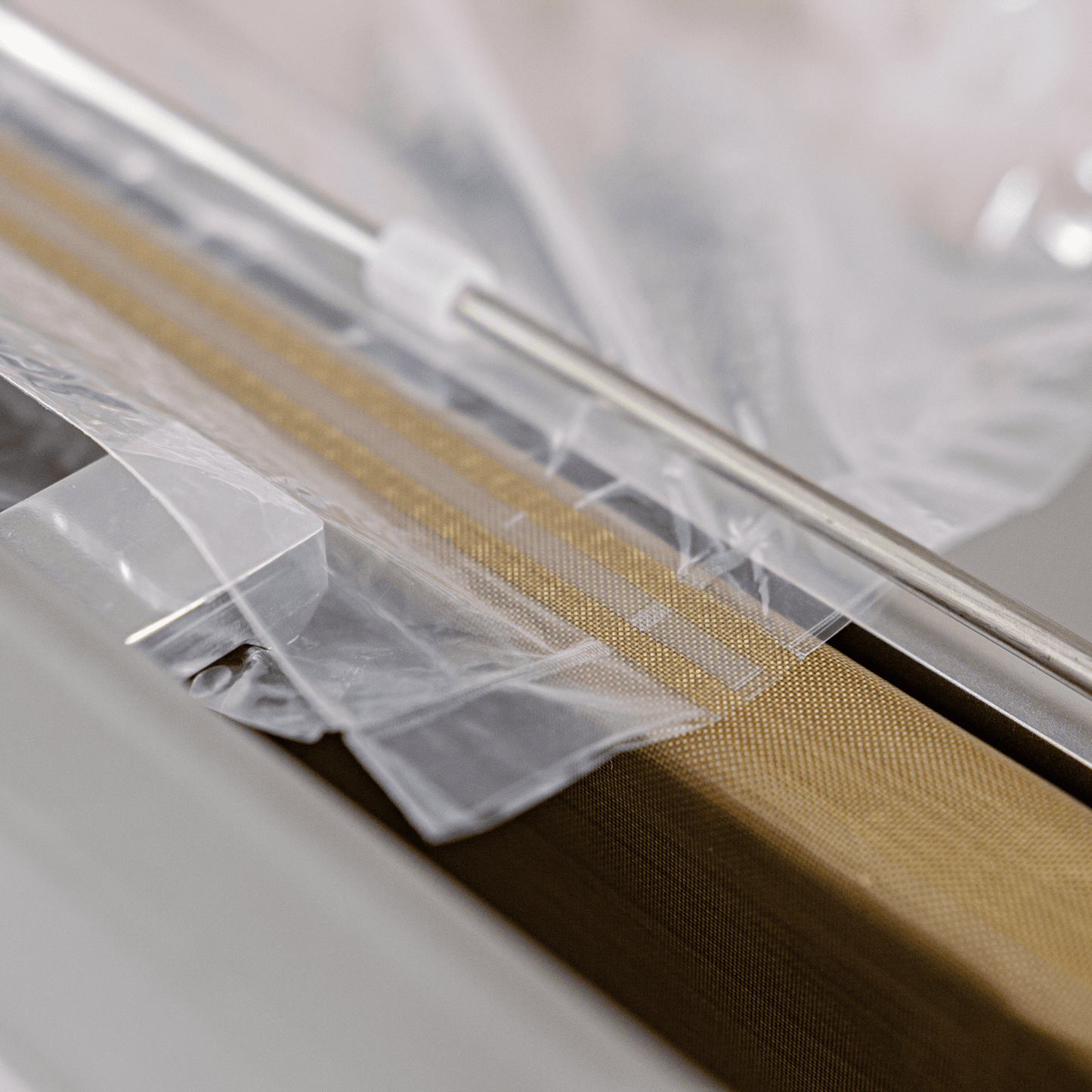

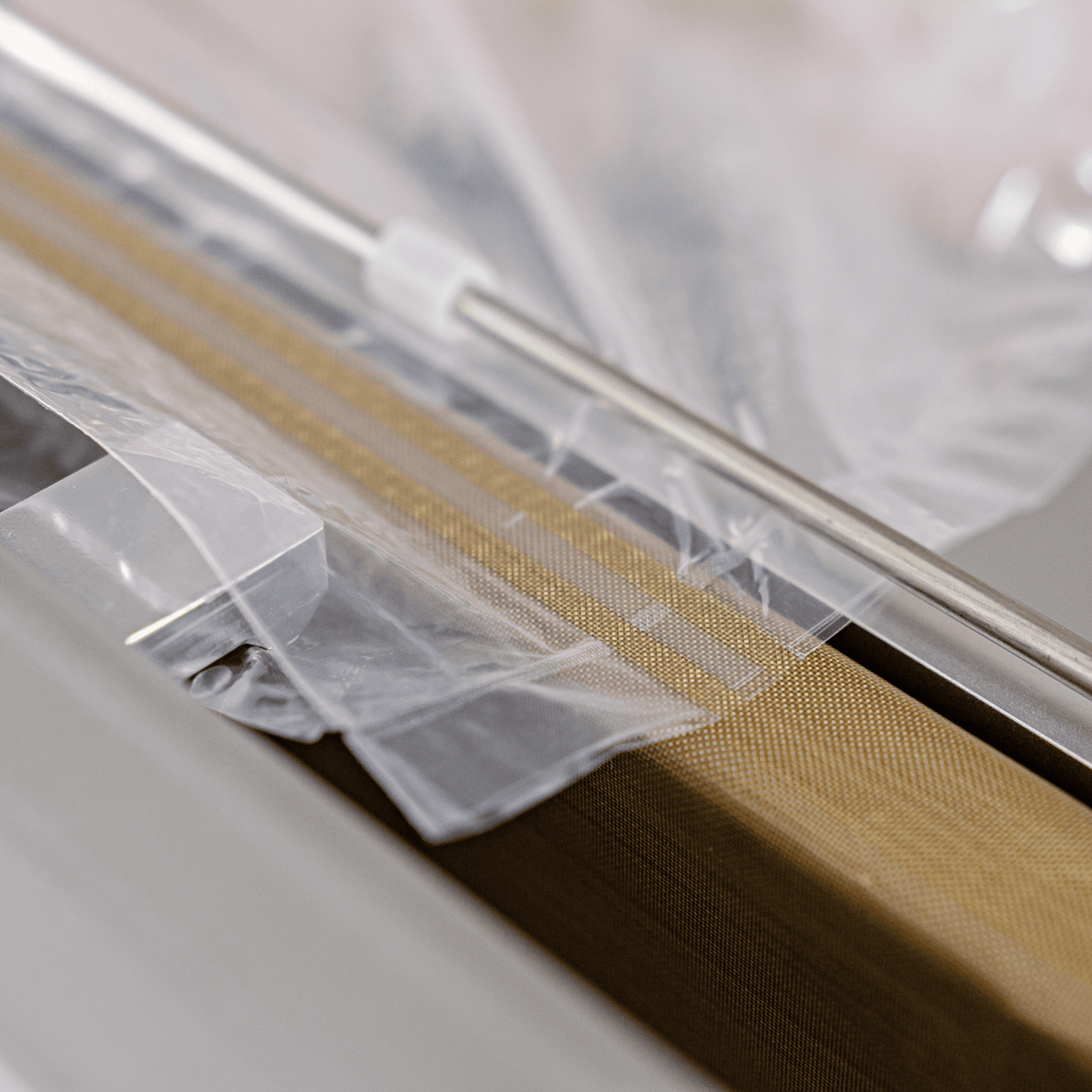

0.14 inches (2 heat-resistant tapes for heat-sealing bar)

|

| Heat-sealing bar length

|

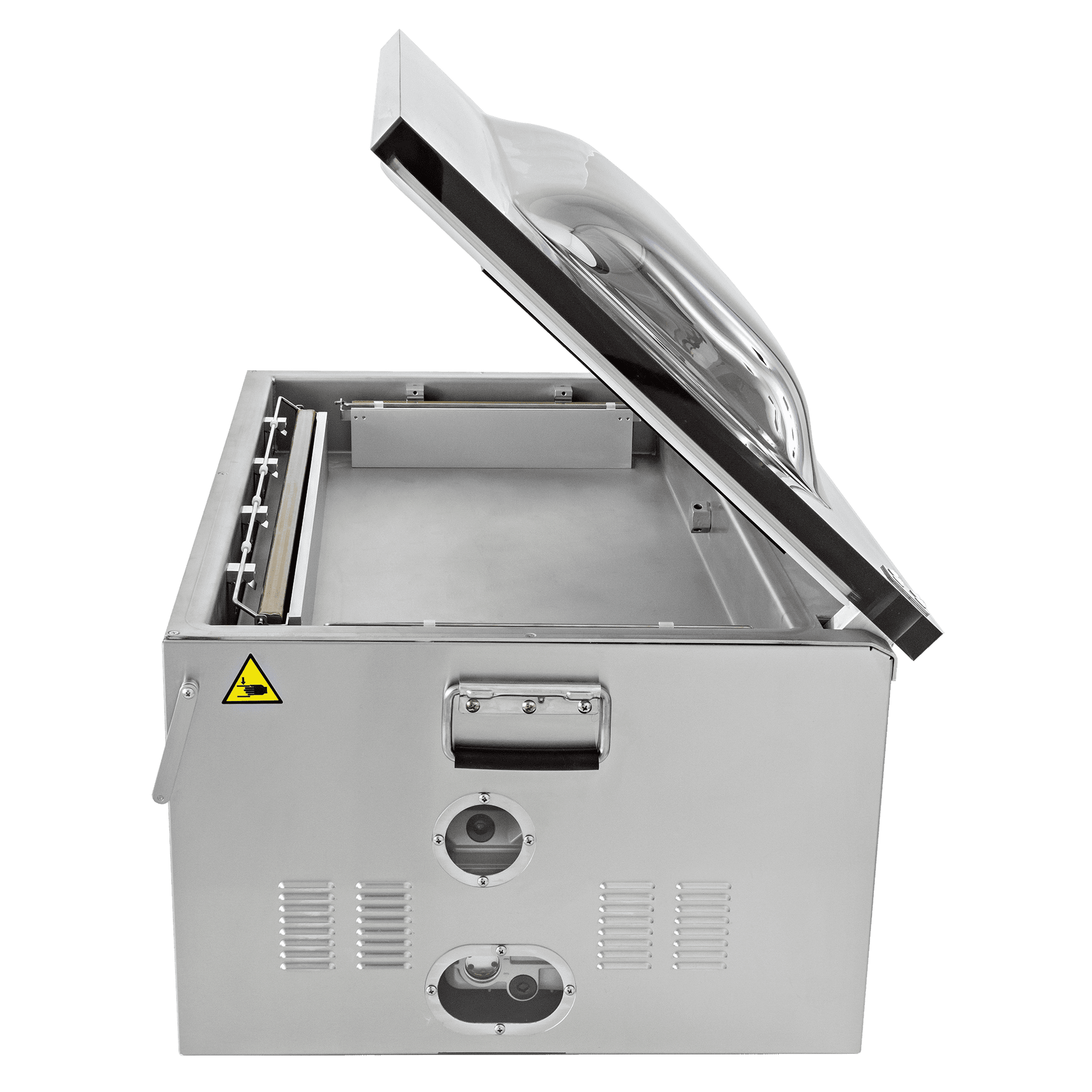

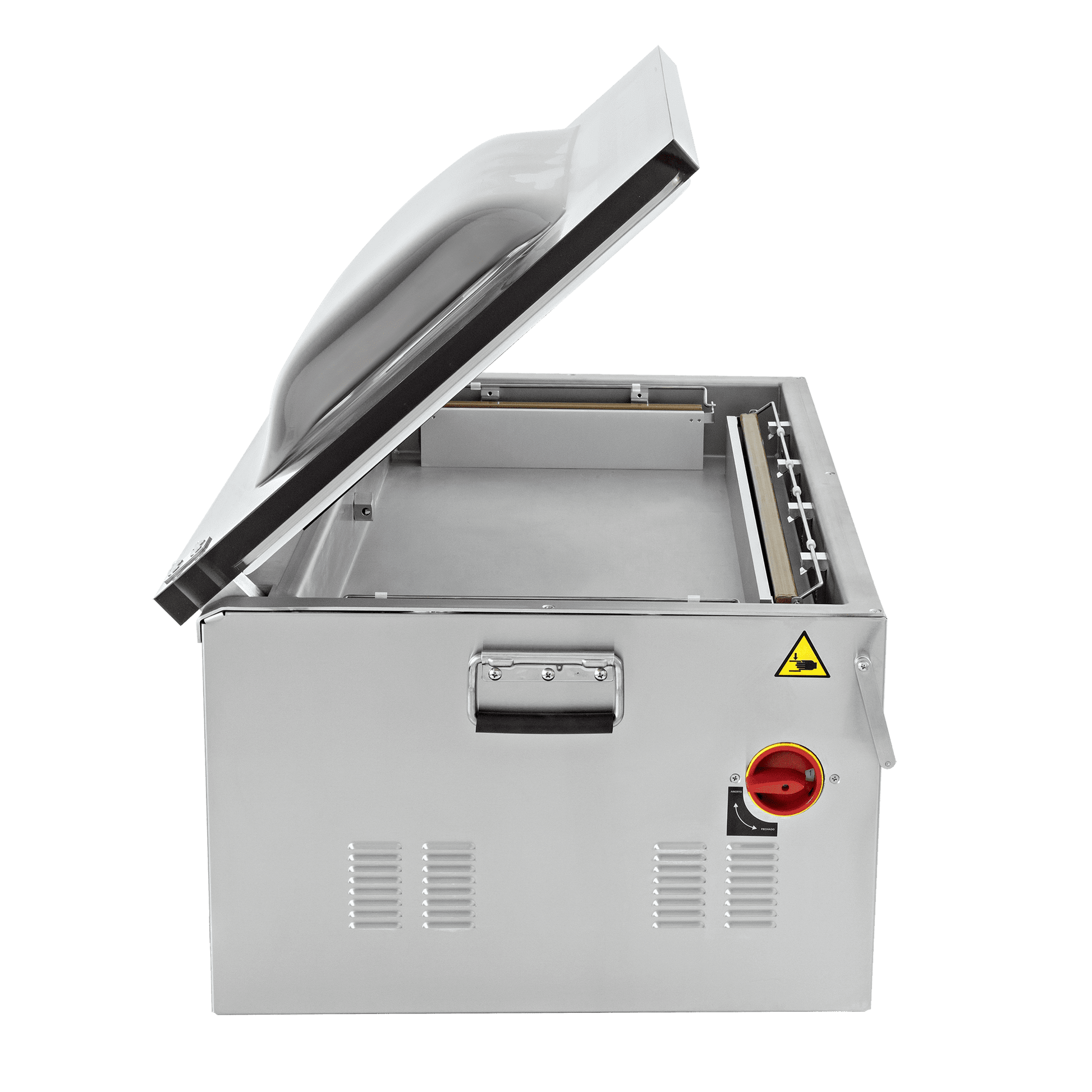

13 inches (2 bars) ∕ 686 mm (1 bar)

|

| Packaging maximum width

|

27 inches (front heat-sealing bar)

|

| Machine dimensions (L x W x H)

|

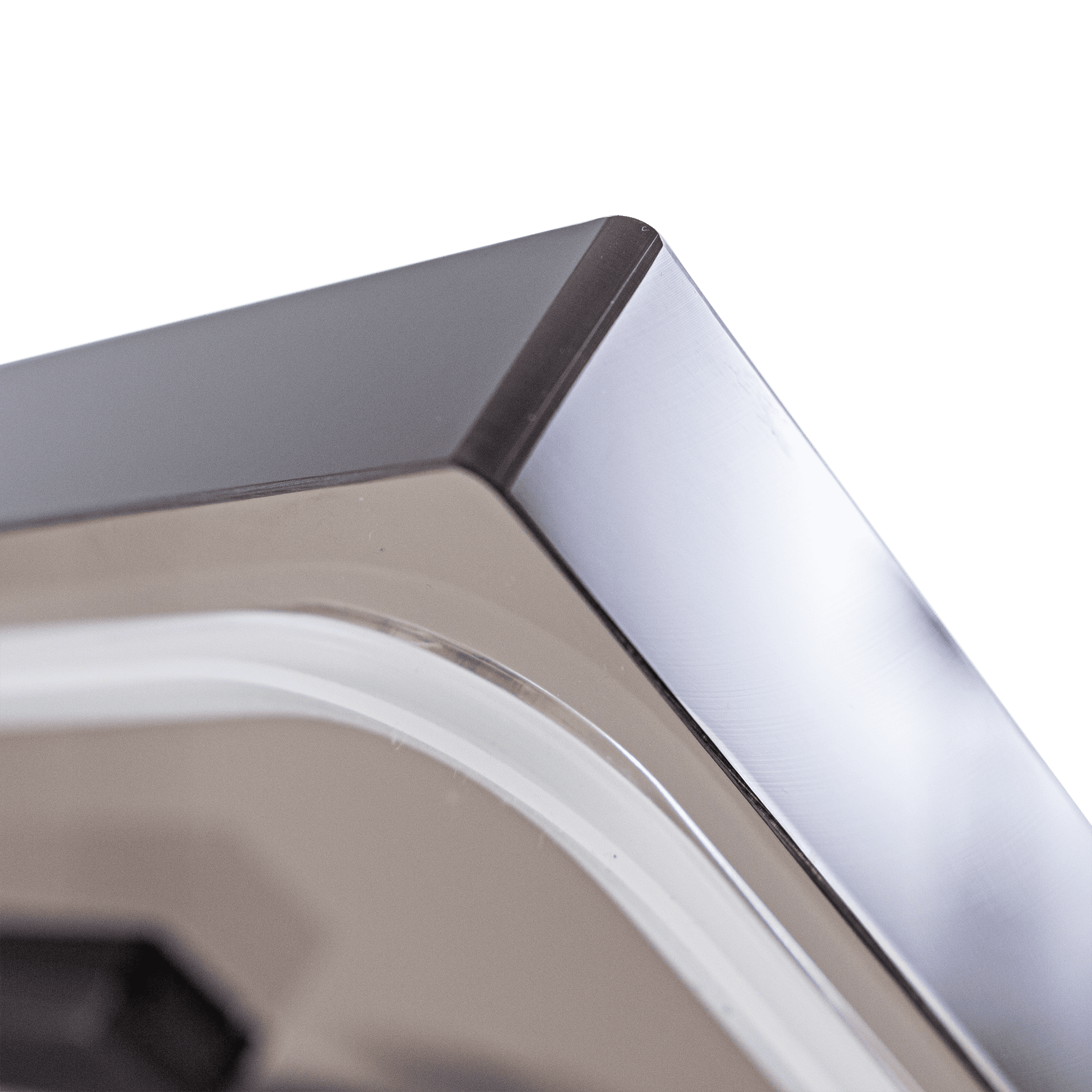

36.9 x 22.9 x 18.6 inches |

About the product

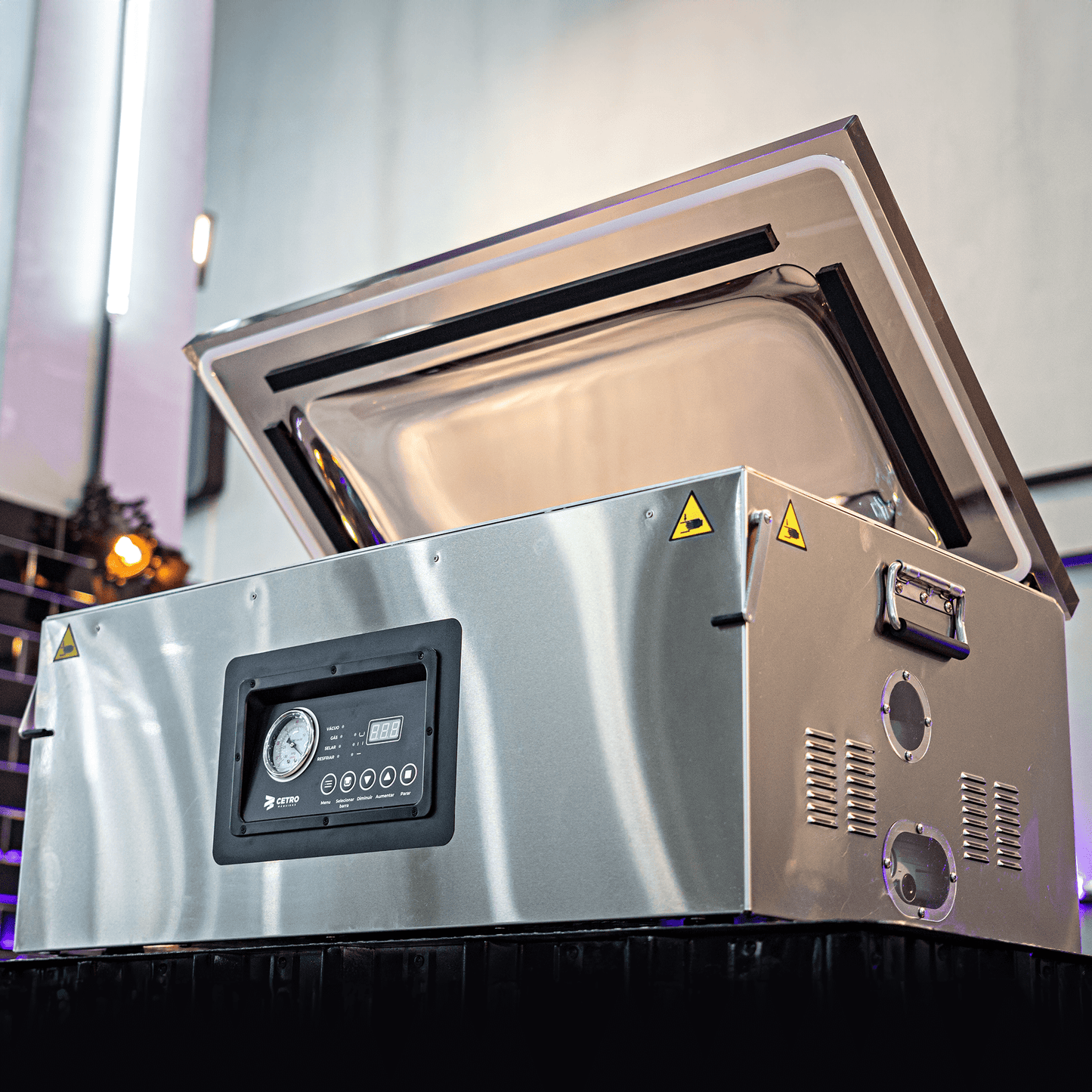

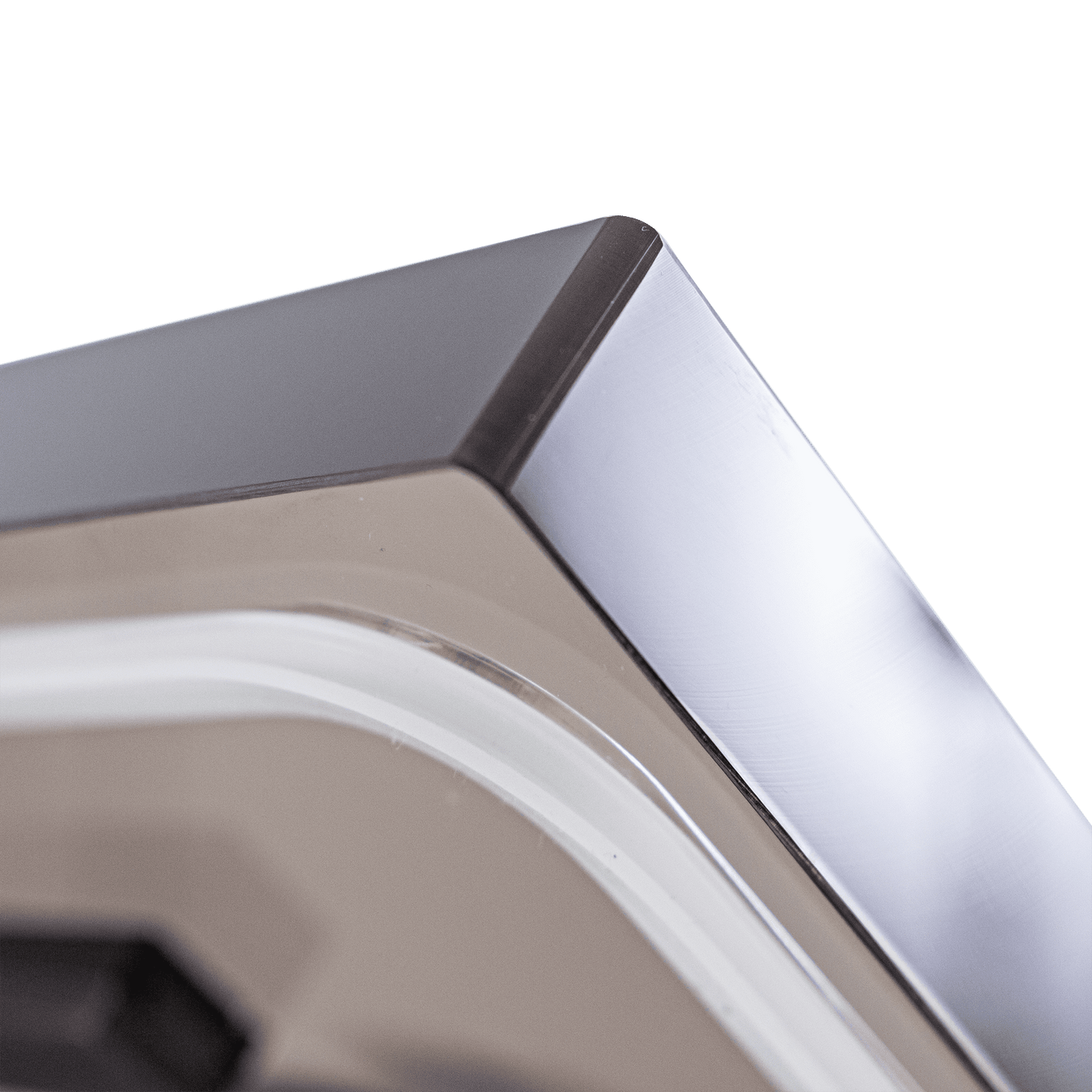

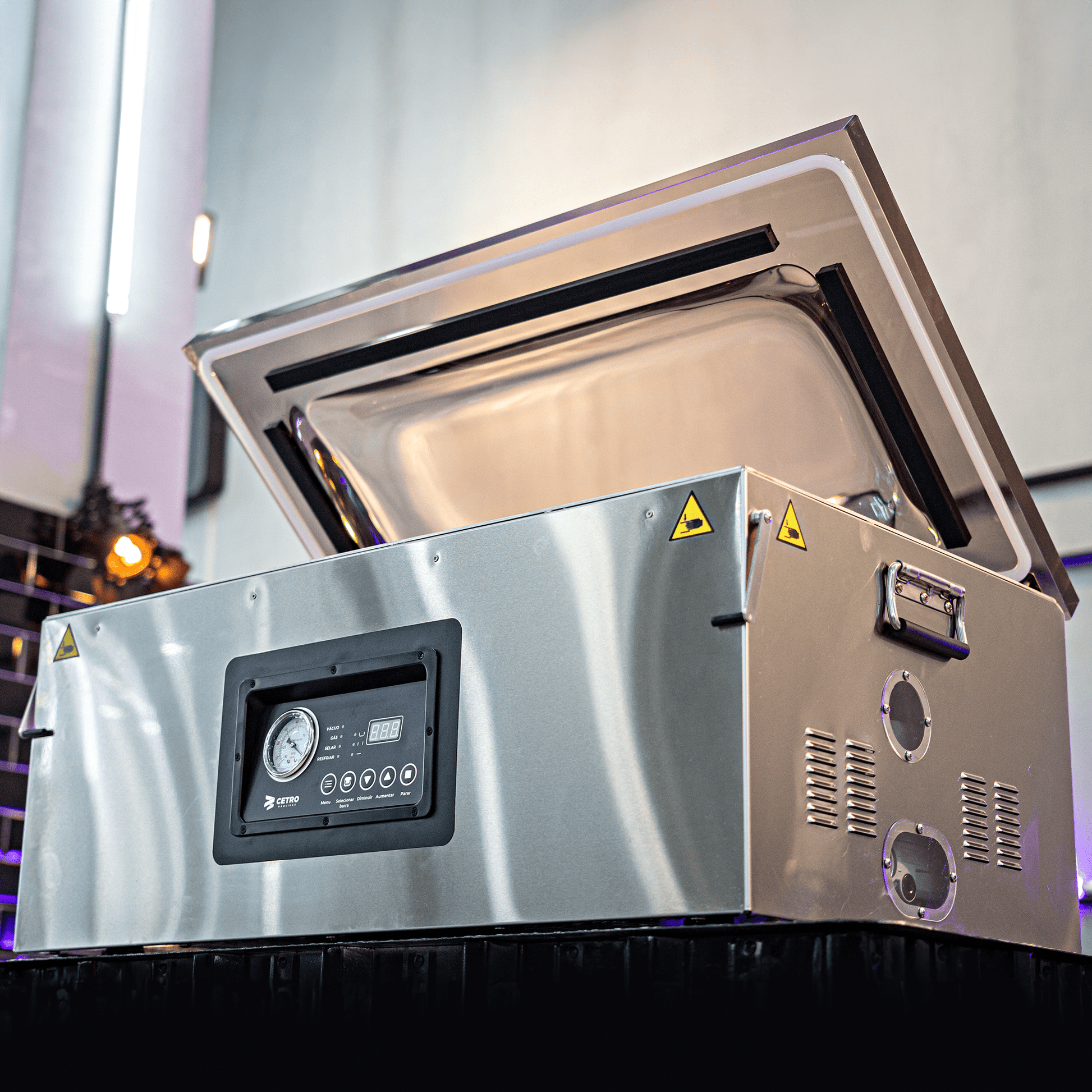

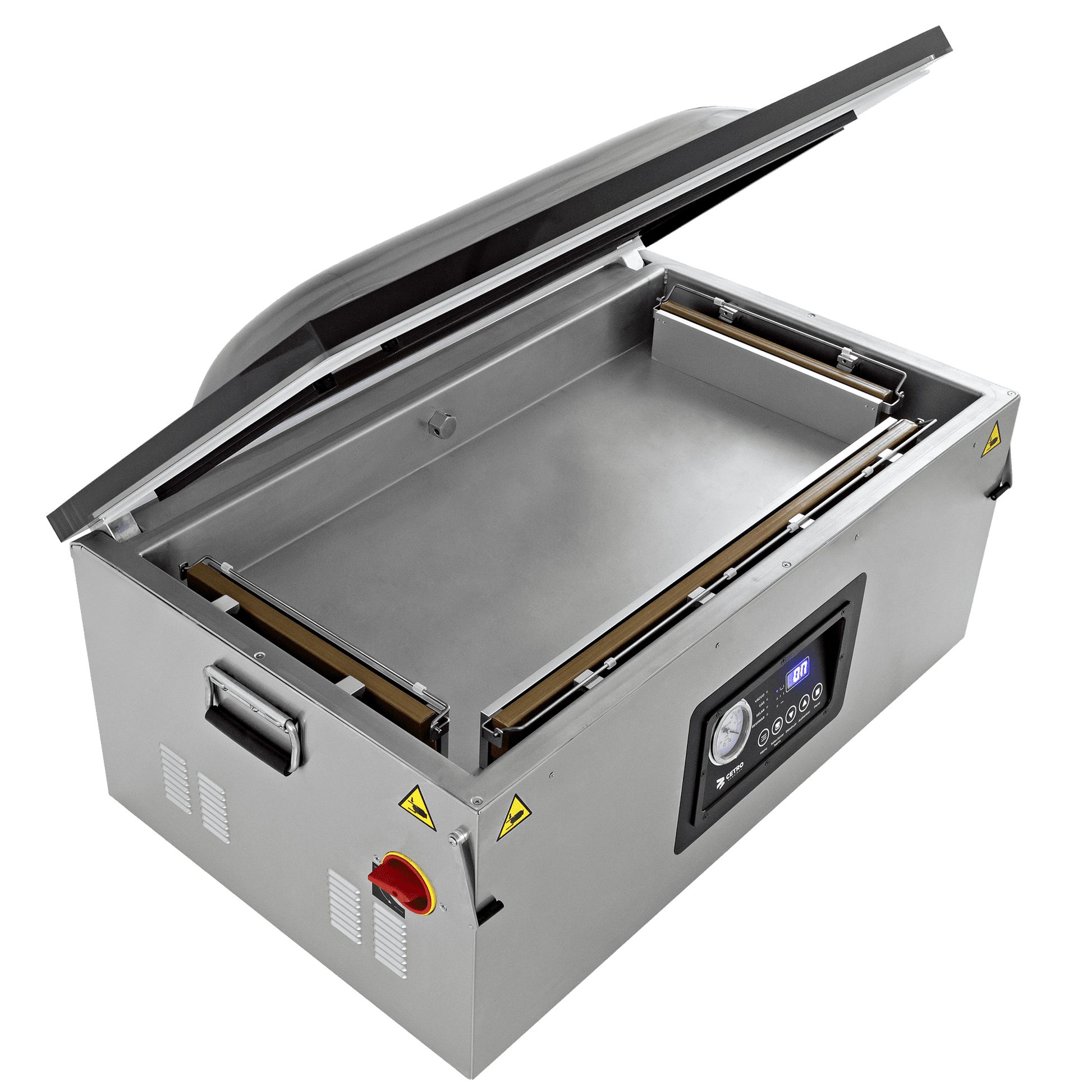

Cetro Chamber Vacuum Sealer CCVS 686 3SB T

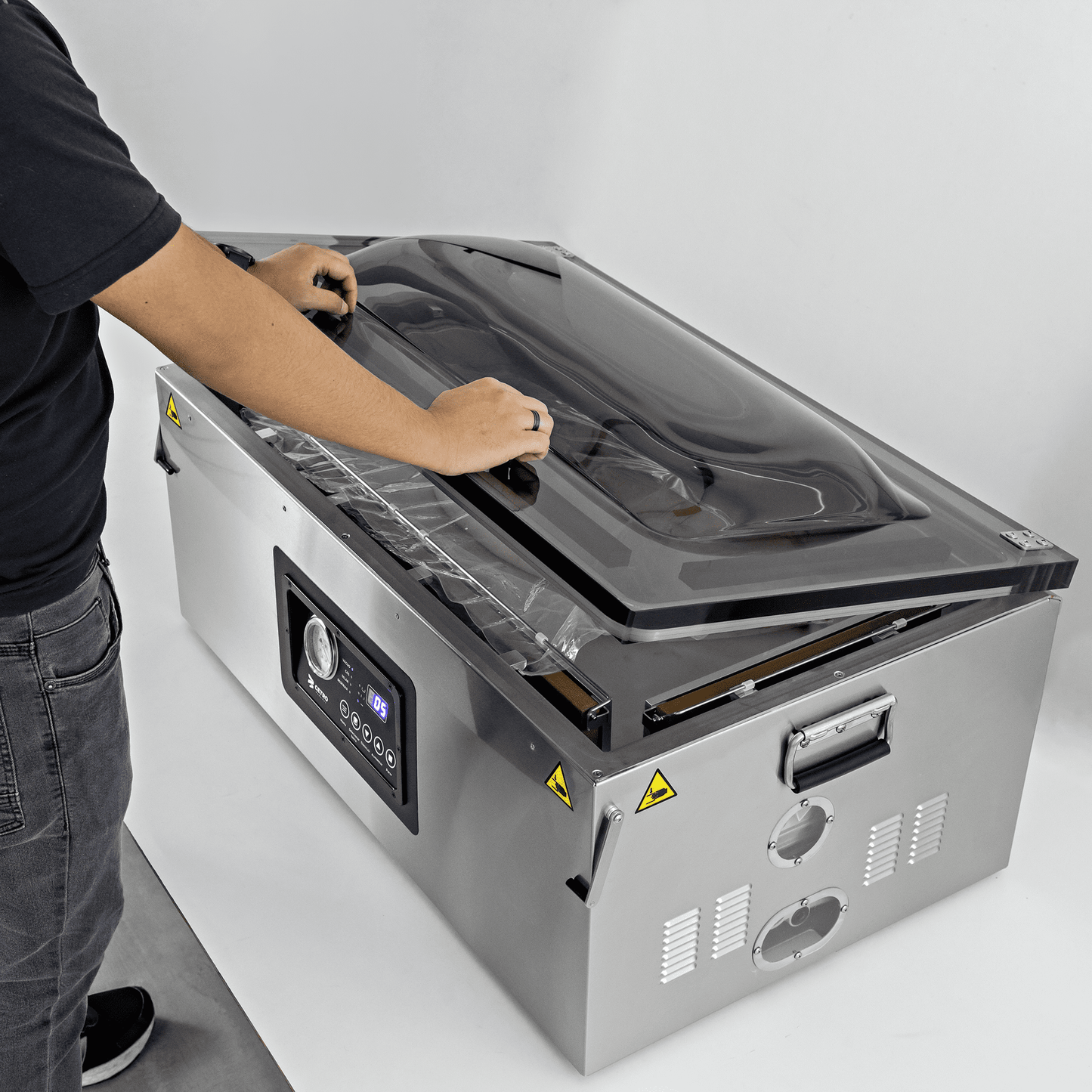

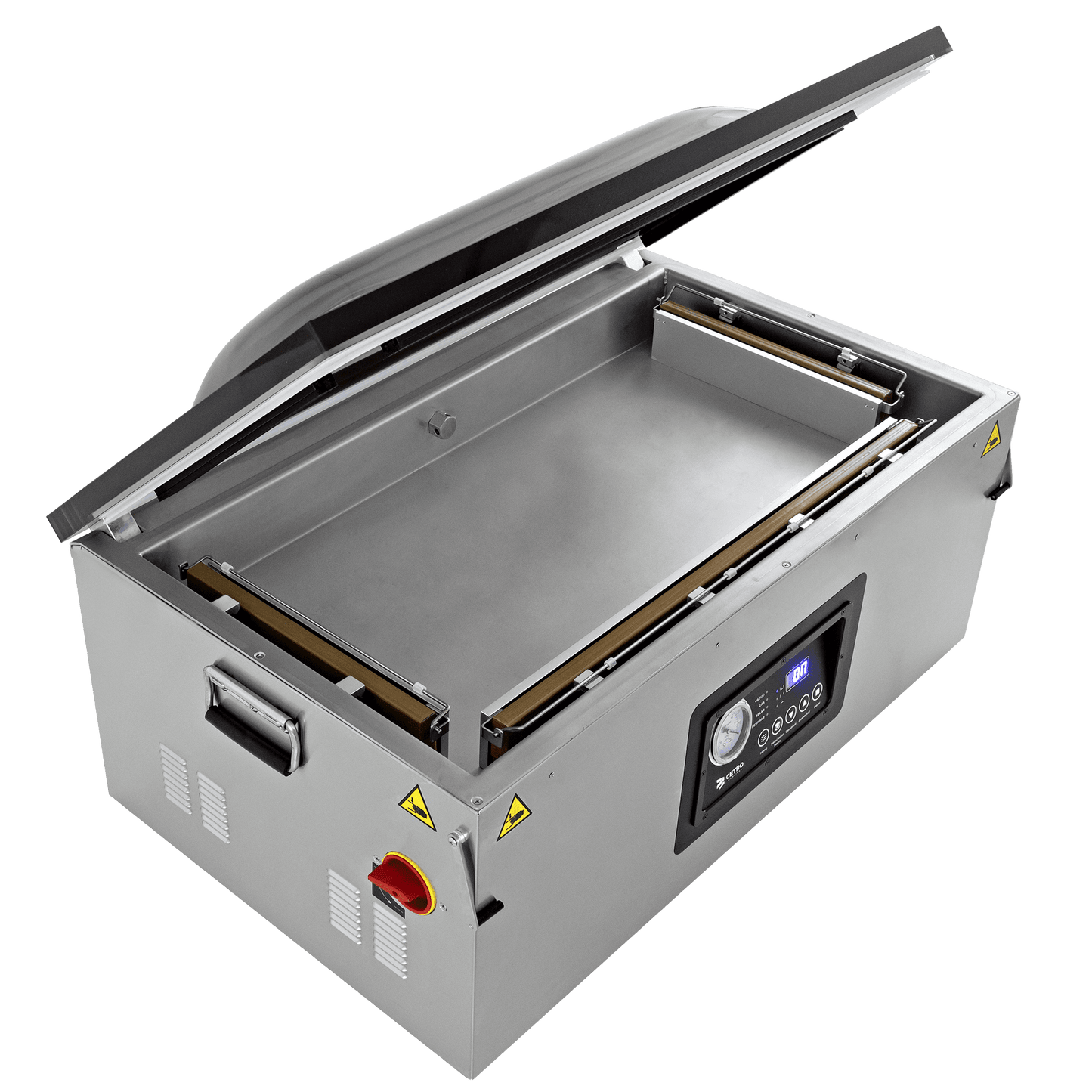

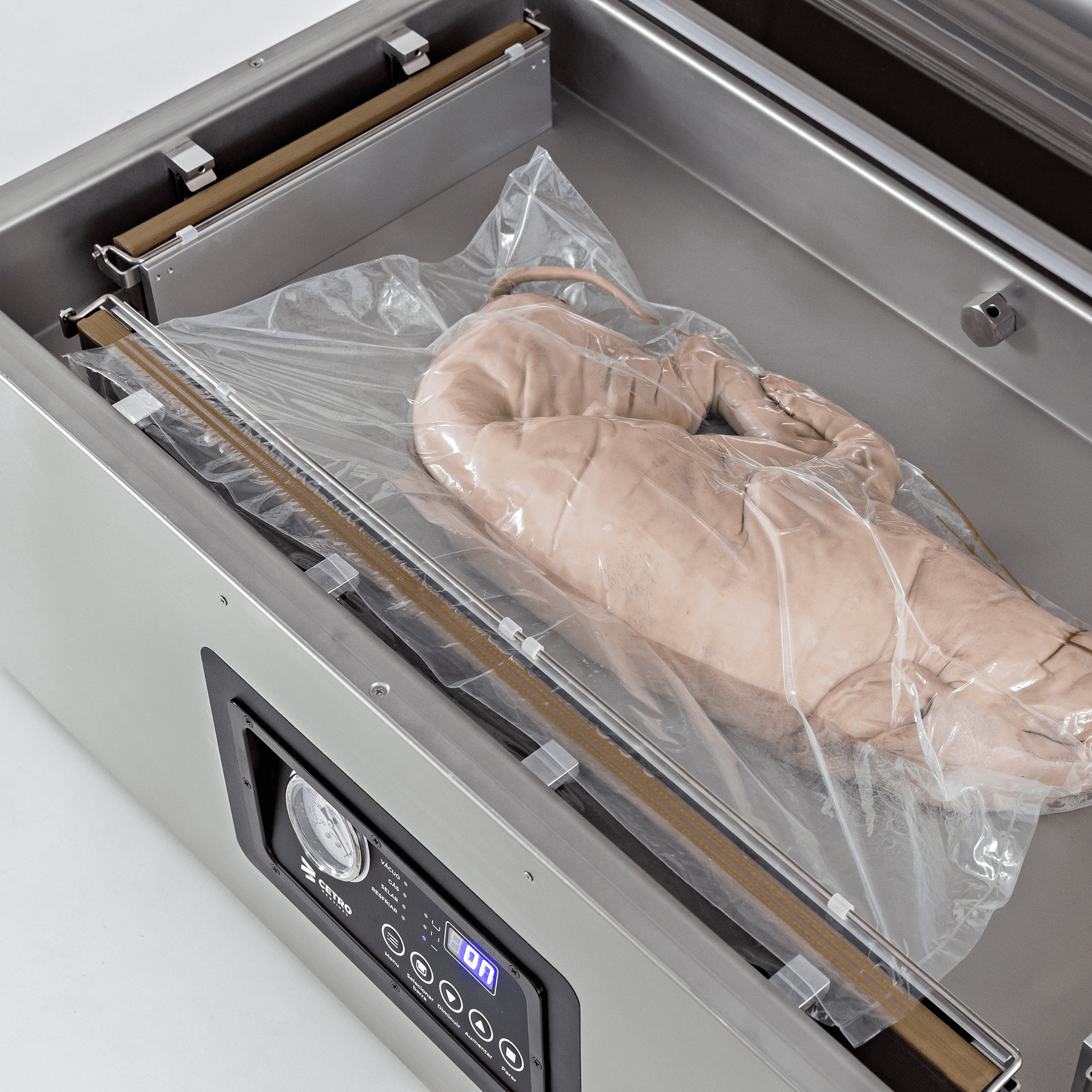

Cetro Chamber Vacuum Sealer CCVS 686 3SB T is an industrial model with a large vacuum chamber and heat-sealing bar with automatic cutting and modified atmosphere injection, highly recommended for industries that produce on a medium or large scale. Além de possibilitar selar grandes quantidades, também confere um excelente acabamento ao produto.

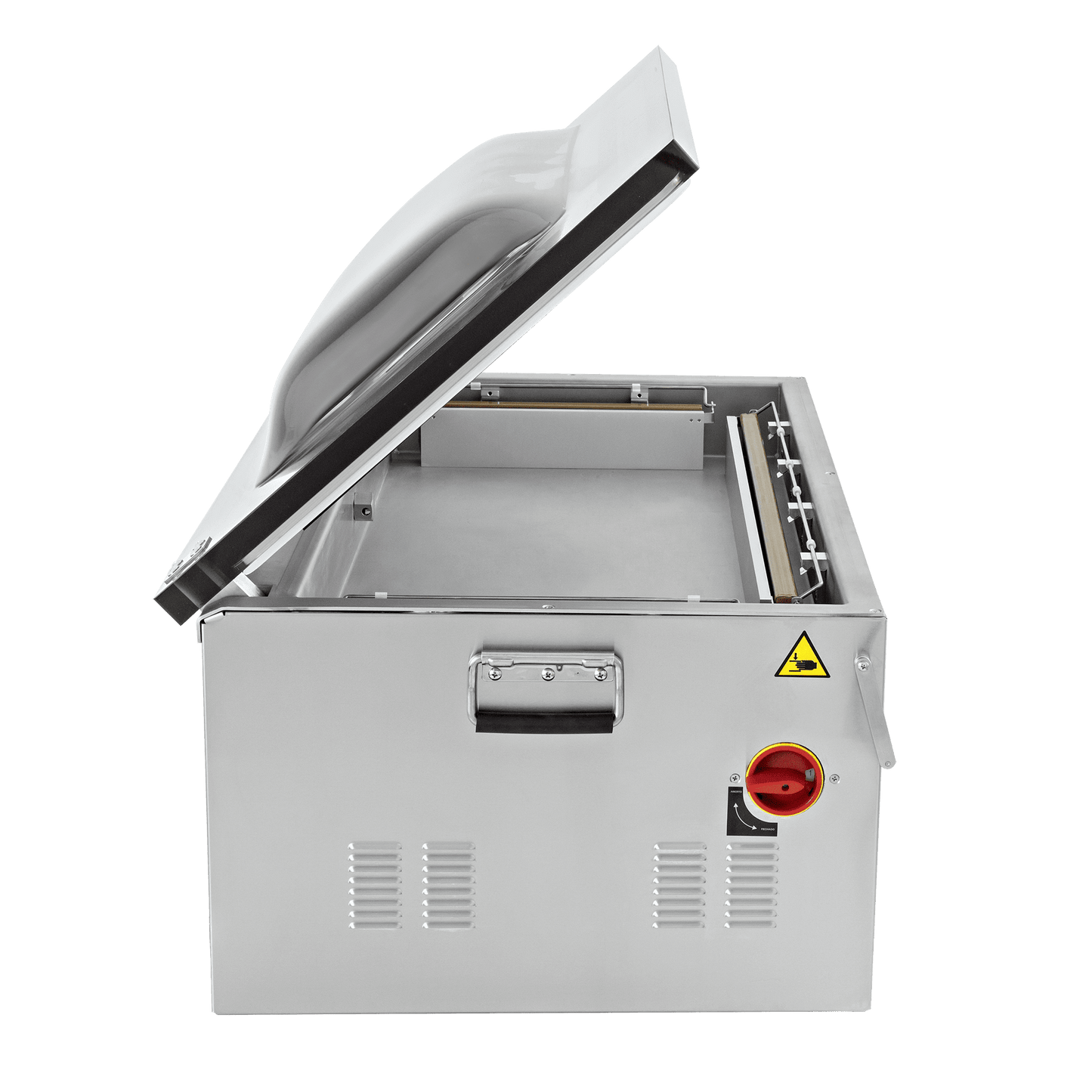

The heat-sealing bars of this model have automatic cutting of the excess packaging for a perfect finish. Its panel has practical functions that make the machine easy to operate and can be handled by operators without much experience. In the panel, it is possible to adjust the sealing time and temperature.

POWERFUL MACHINE

Extremely robust and industrial equipment with a powerful vacuum pump, ideal for productions that require a large machine with high productivity.

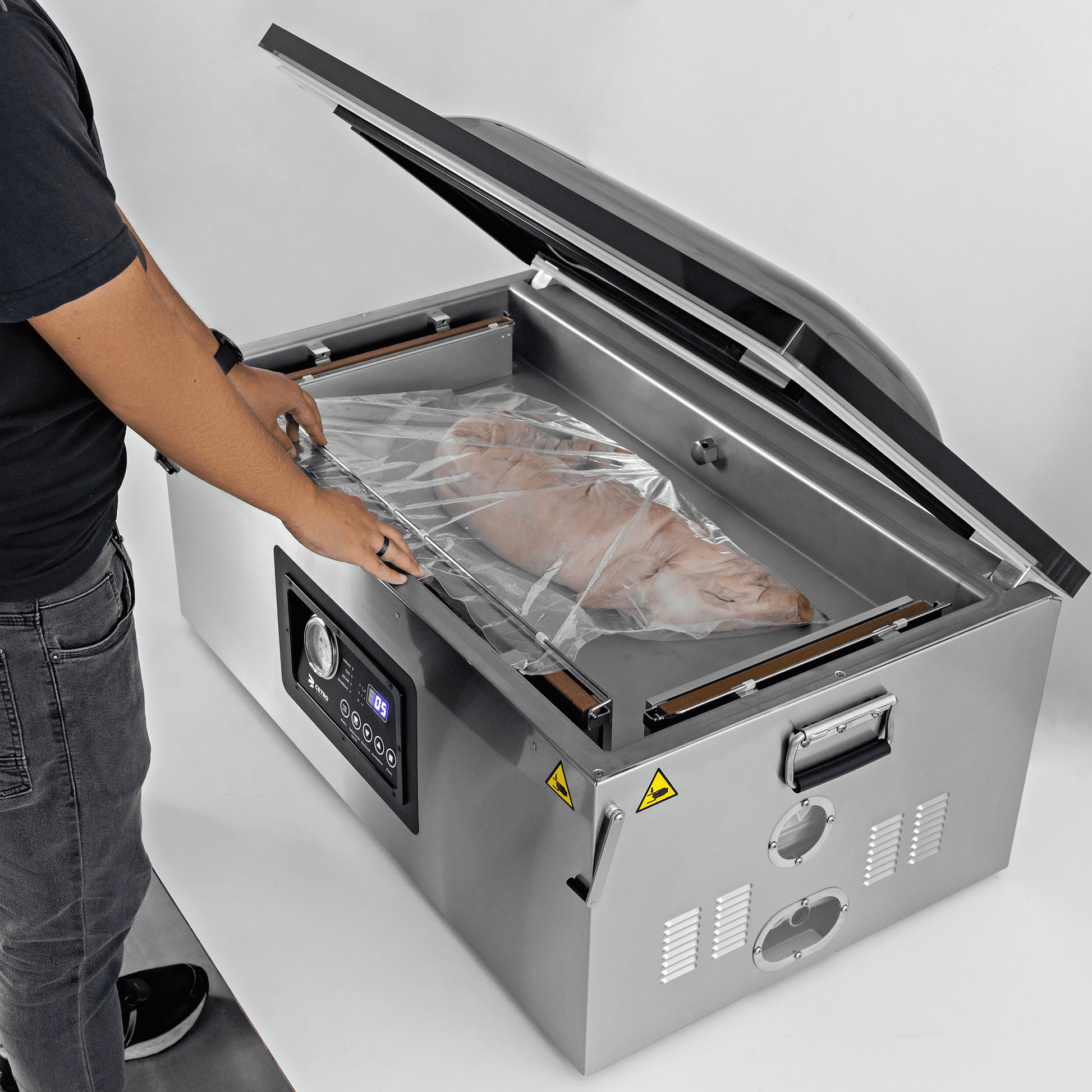

DIVERSITY OF APPLICATION

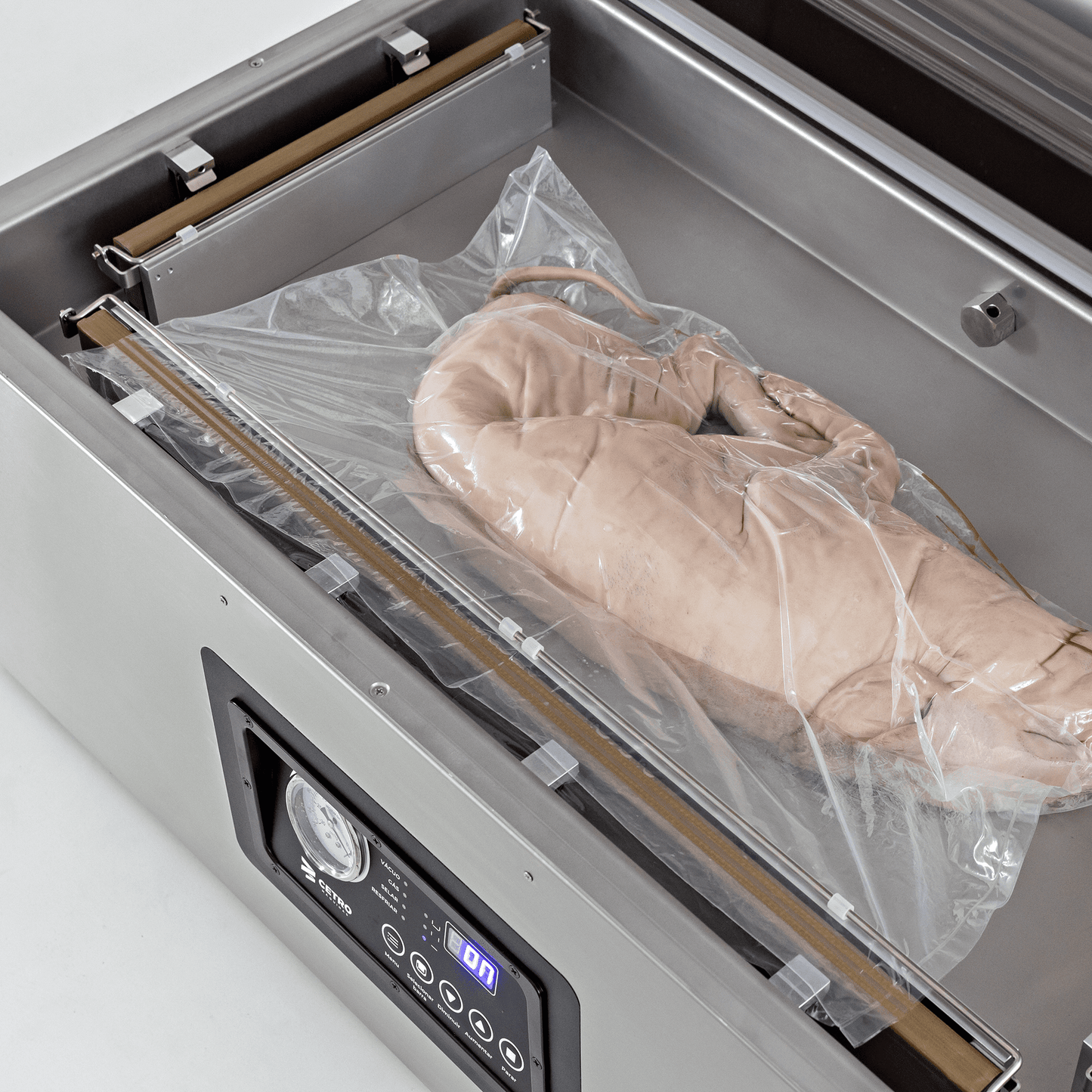

Cetro Chamber Vacuum Sealer CCVS 686 3SB T can vacuum seal numerous products in different market segments, such as meats, snacks, fish, vegetables, cereals, skewers, sausages, pizzas, palm hearts, sliced cold cuts, poultry, pasta, cheeses, frozen foods, mushrooms, fruit and vegetables and much more.

Vacuum packaging improves the presentation and appearance of products, makes them easier to display in sales areas, reduces storage space, and eliminates the risk of contamination through handling.

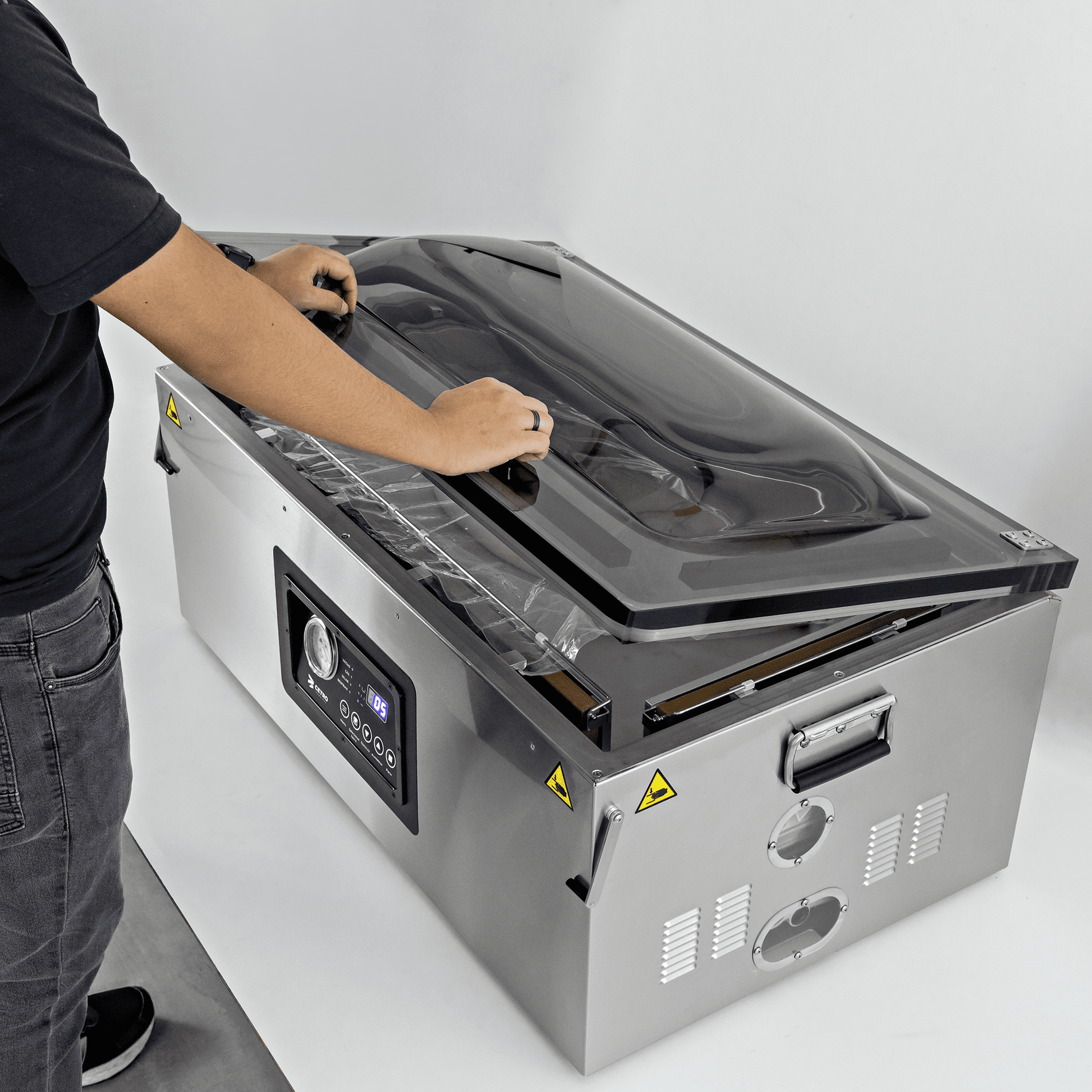

INCREASE YOUR PRODUCTIVITY

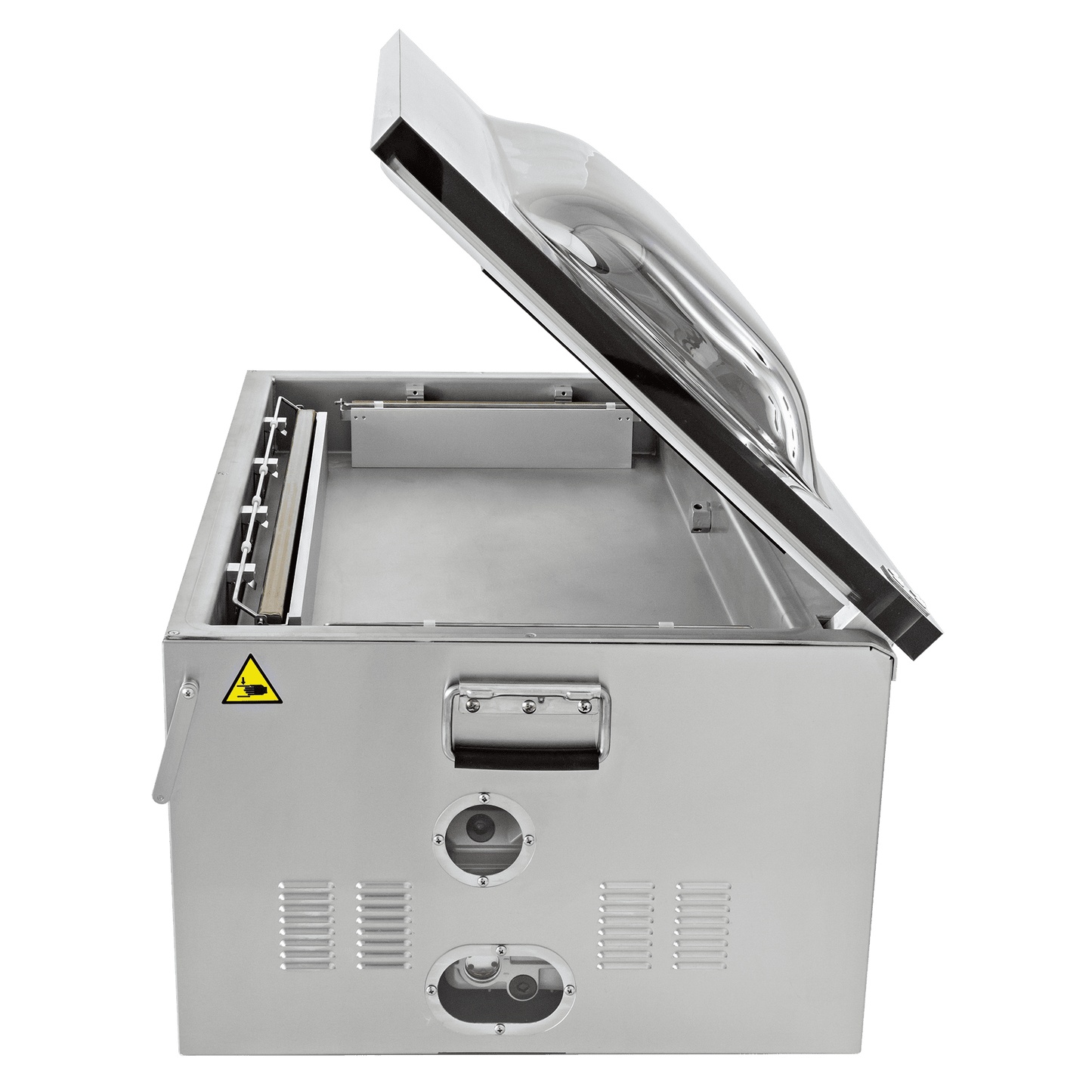

Cetro Chamber Vacuum Sealer CCVS 686 3SB T has three sealing bars for more agile sealing. With a length of 13 inches for the two side heat-sealing bars and 27 inches for the front heat-sealing bar, this configuration allows for more efficient and faster sealing.

The heat-sealing bars can work with different adjustments: two smaller bars can be used simultaneously, all three bars can be activated at the same time, or only one larger bar can be used in isolation, with the adjustment easily made via the machine's panel.

In addition, each heat-sealing bar has a heat-resistant tape width of 0.14 inches with two resistors per bar, which contributes to a robust and secure seal for vacuum-packed products.

WHAT ARE THE MAP FUNCTIONS?

The use of a modified atmosphere in packaging offers several benefits, such as increasing the shelf life of products, preserving the characteristics of taste, texture, and nutrients, reducing the development of bacteria and fungi, as well as minimizing the use of preservatives, and reducing waste.

MAP injection is common for packaging dairy products, dry foods, bakery products, seafood, fruit, vegetables, and red meat, guaranteeing the integrity of the products from production to the sales area.

This technique preserves the crispness and natural characteristics of the food, using gases such as carbon dioxide, nitrogen, and oxygen to maintain the quality of the packaged food, inhibiting microbiological activity, preventing oxidation, and maintaining the internal volume of the packaging.

Need Help?

Click here to speak to a sales representative now or call +1 (800) 917-0511 and ask all your questions.

Easy Payment

Easy Payment Consulting with Experts

Consulting with Experts Secure Purchase

Secure Purchase