Technical Sheet

| Model

|

CCVS 500 T |

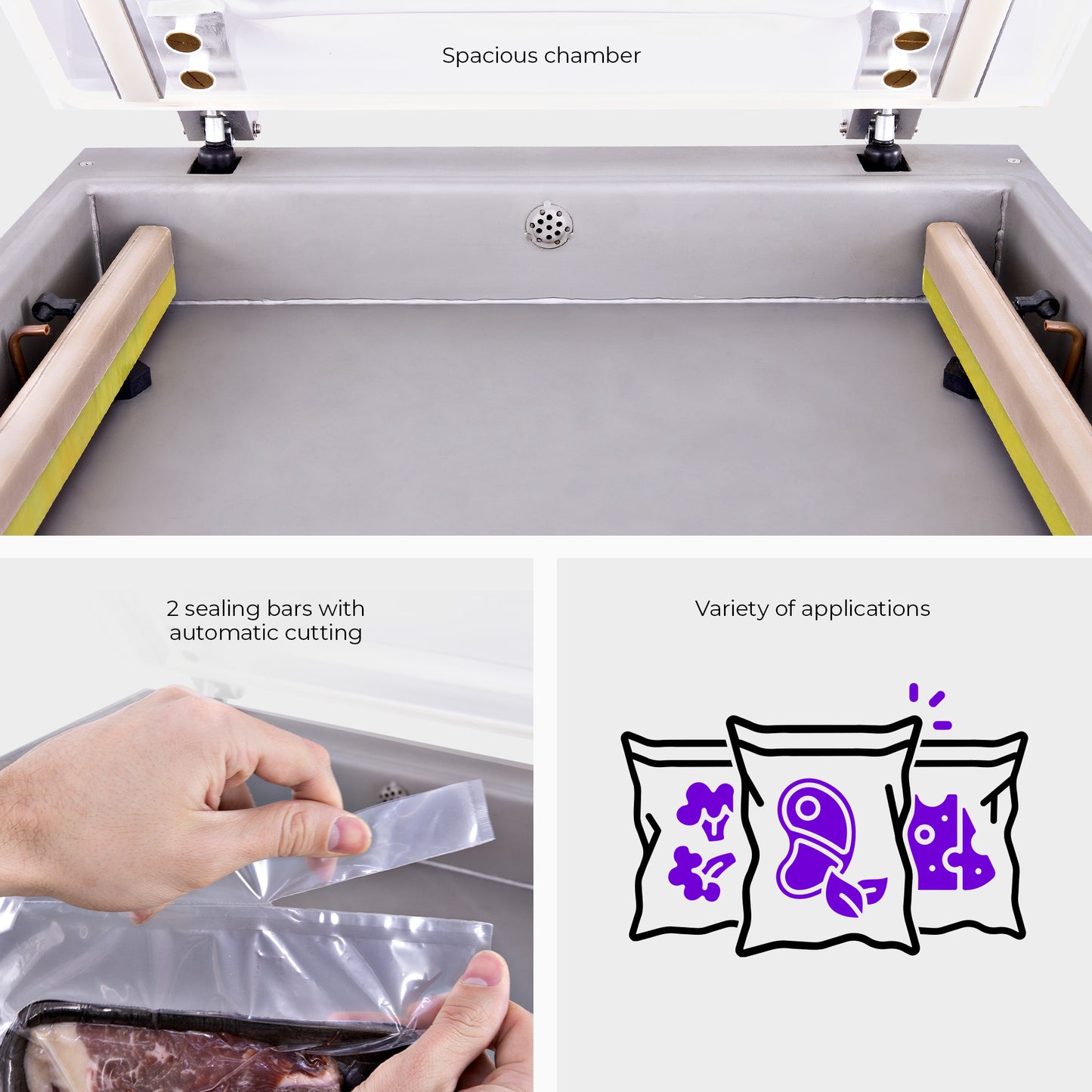

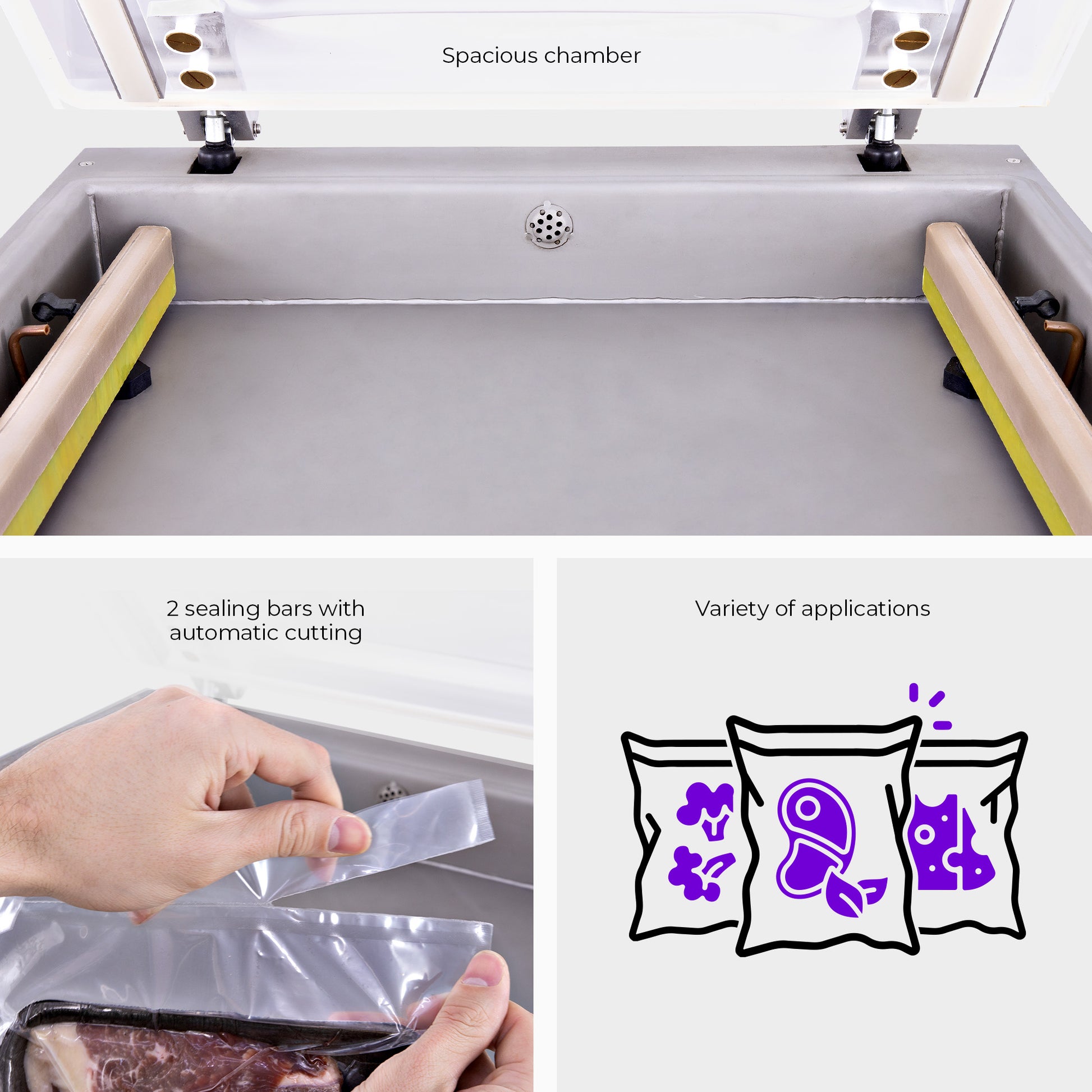

| Number of heat-sealing bars

|

2 |

| Heat-sealing bar size |

19.7 x 0.4 inches |

| Usable space

|

16.9 x 20.7 inches |

| Maximum height

|

5.9 inches |

| Machine dimensions (L x W x H)

|

23.2 x 24.8 x 22.4 inches |

| Weight

|

72 kg

|

About the product

Cetro Chamber Vacuum Sealer CCVS 500 T

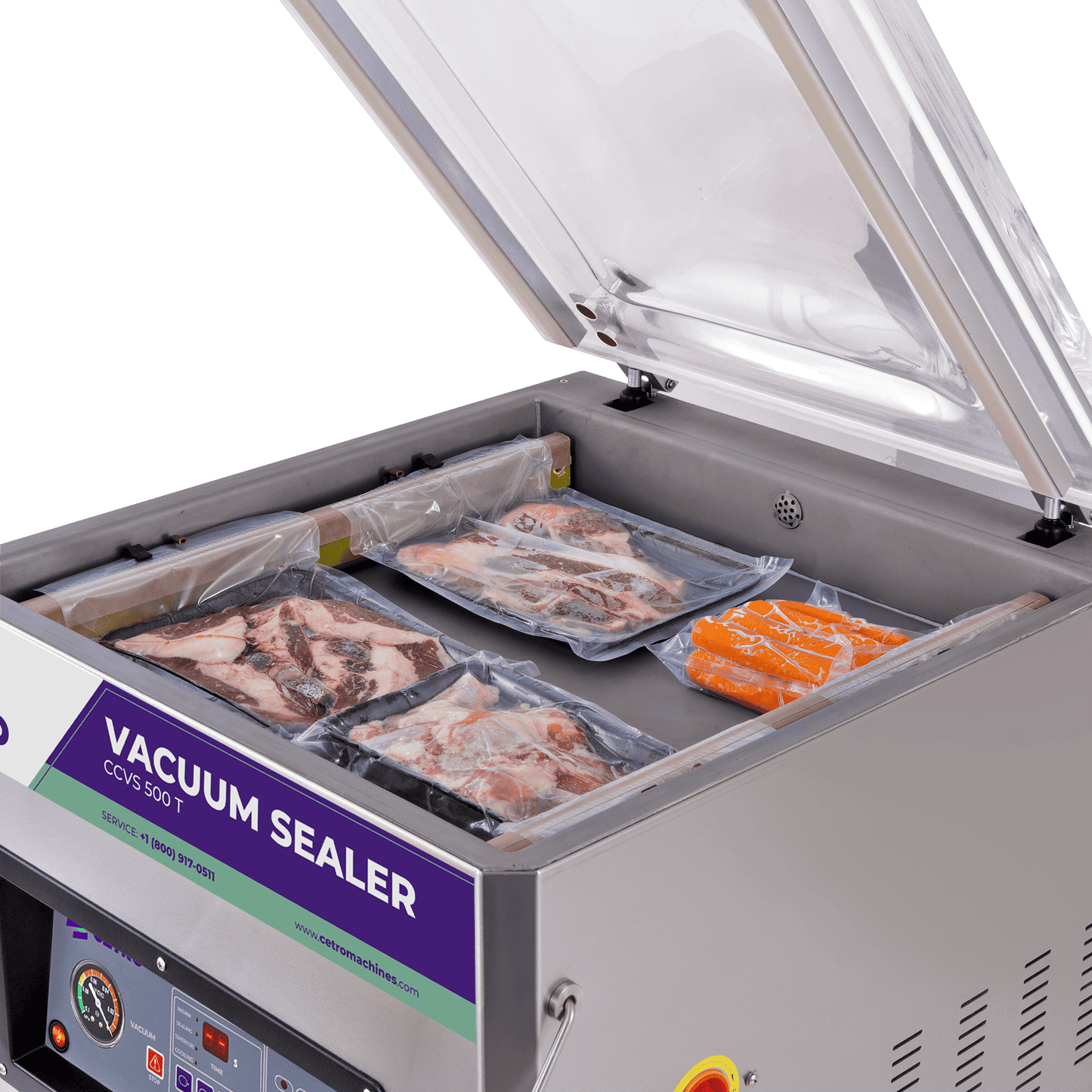

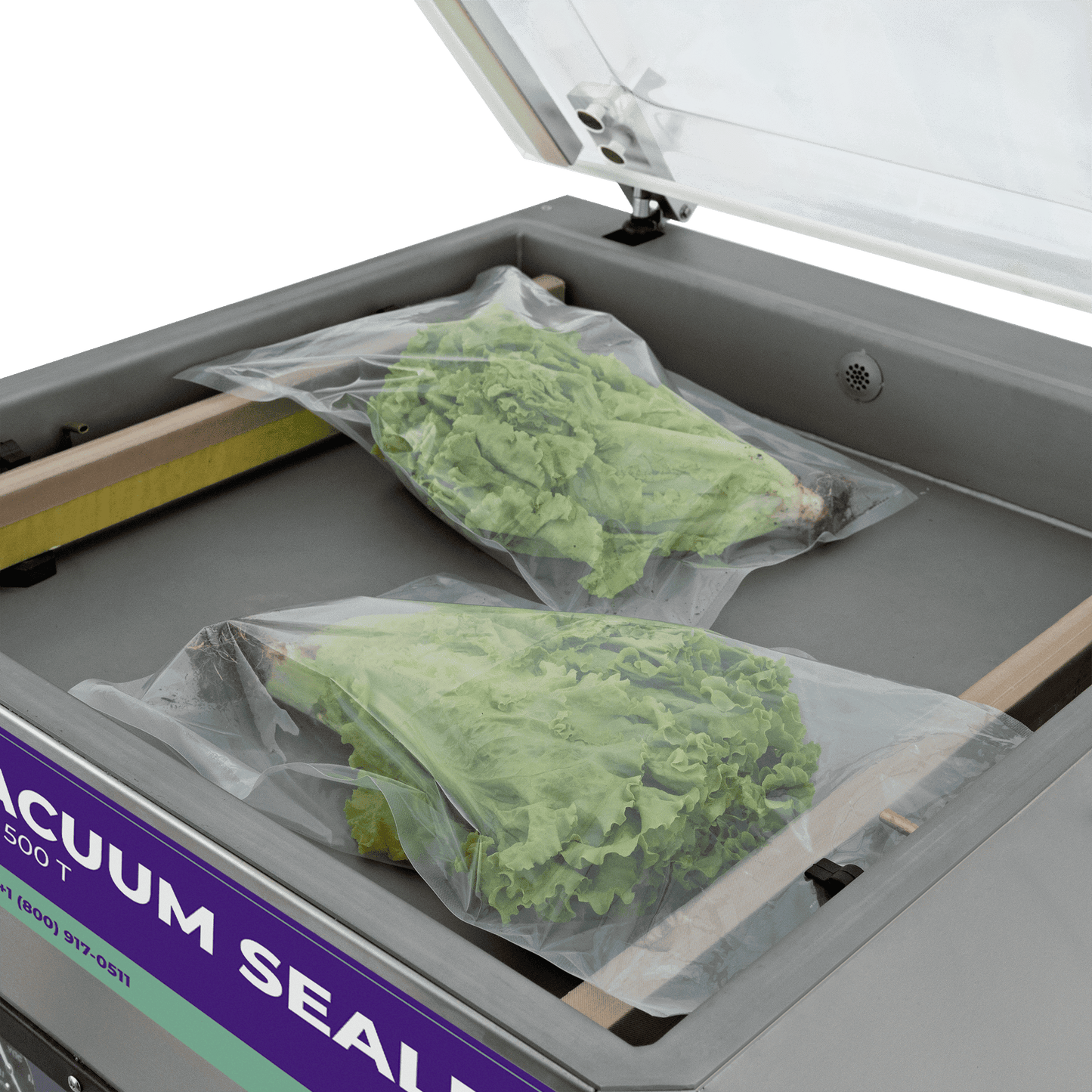

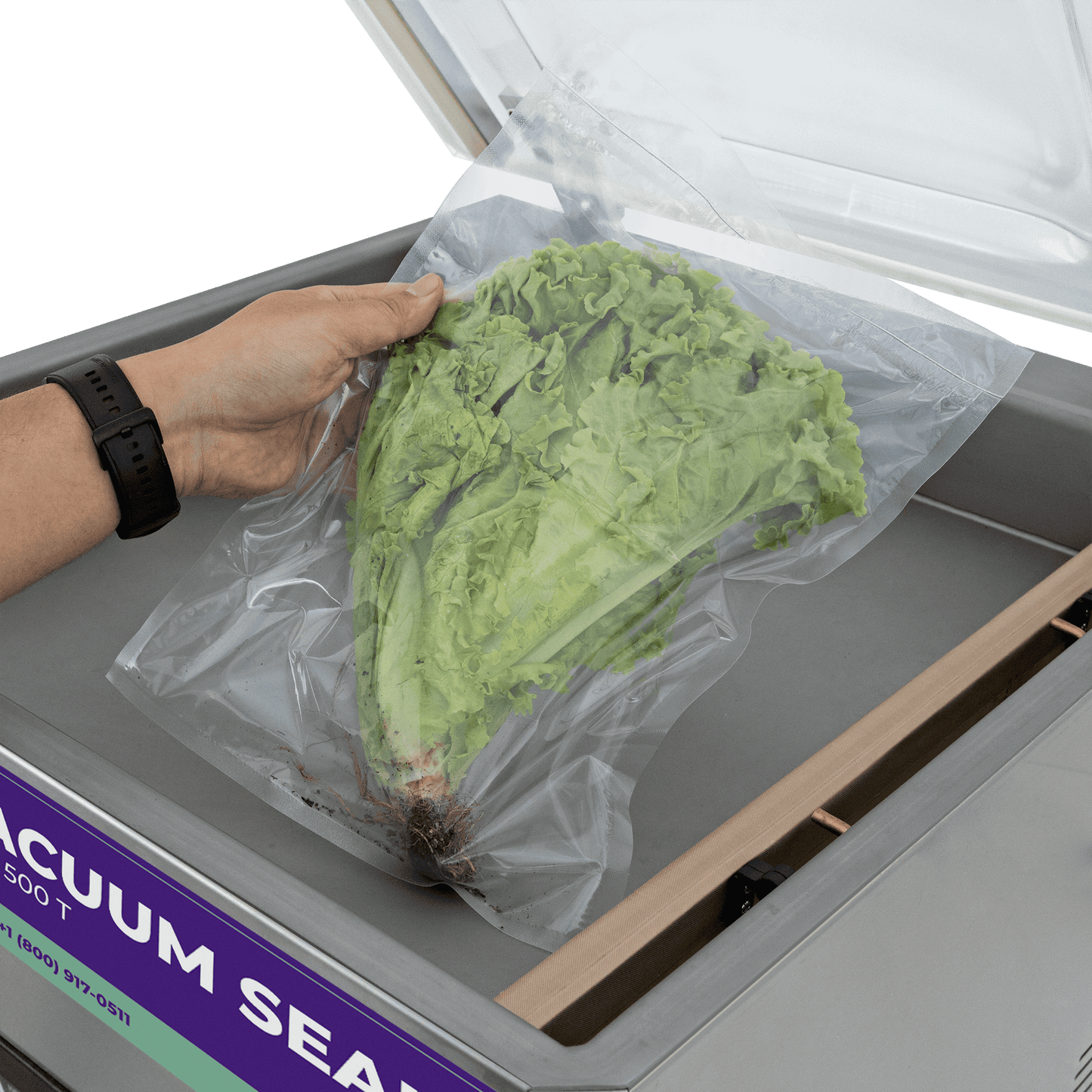

Cetro Chamber Vacuum Sealer CCVS 500 T is an industrial model with a large vacuum pump, two heat-sealing bars with automatic cuts, and the insertion of a modified atmosphere. It is highly recommended for industries that produce on a medium or large scale.

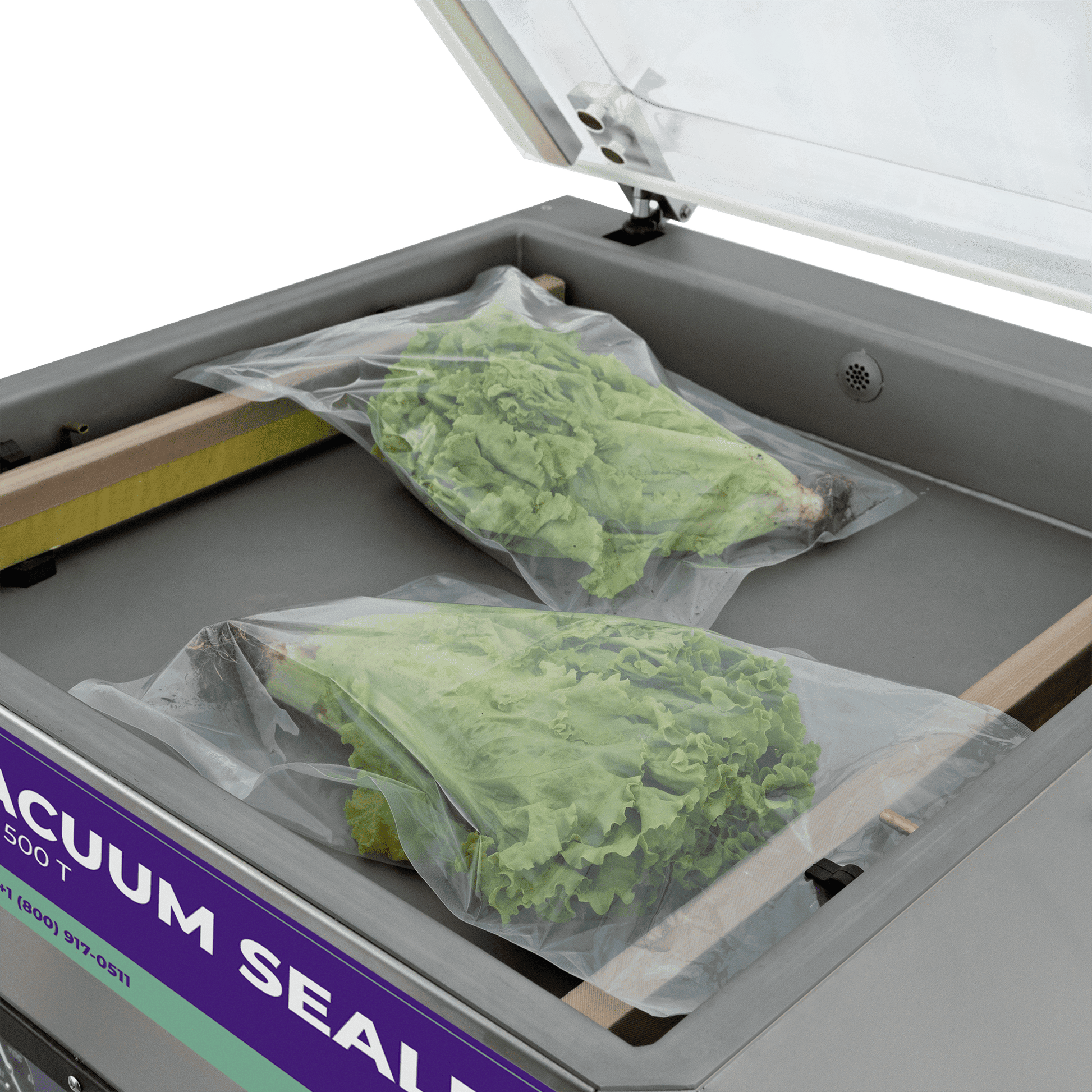

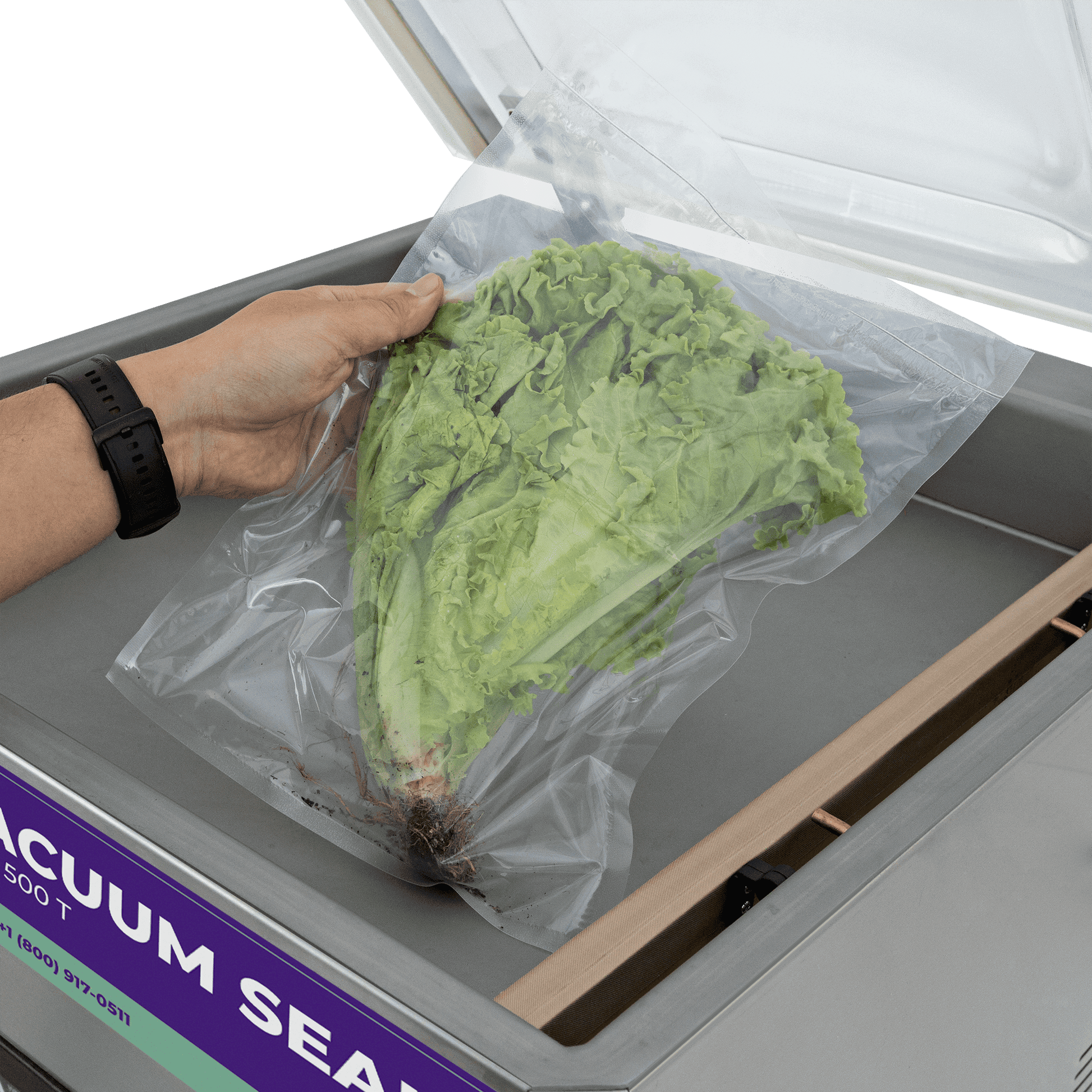

Its heat-sealing bar size of 20 inches and automatic cut of the material excess ensures a unique finish. It has the option to work with one or two heat-sealing bars to perfectly satisfy all business demands.

The panel of the CCVS 500 T has practical functions. Even an inexperienced operator can use this equipment with ease. Through the panel, it is possible to adjust the sealing time and temperature and select one or two heat-sealing bars for the processes.

POWERFUL VACUUM PUMP

It is a robust industrial equipment with a vacuum pump capacity of 50 m³/h, ideal for medium or large-scale industries with high productivity.

DIVERSITY OF APPLICATIONS

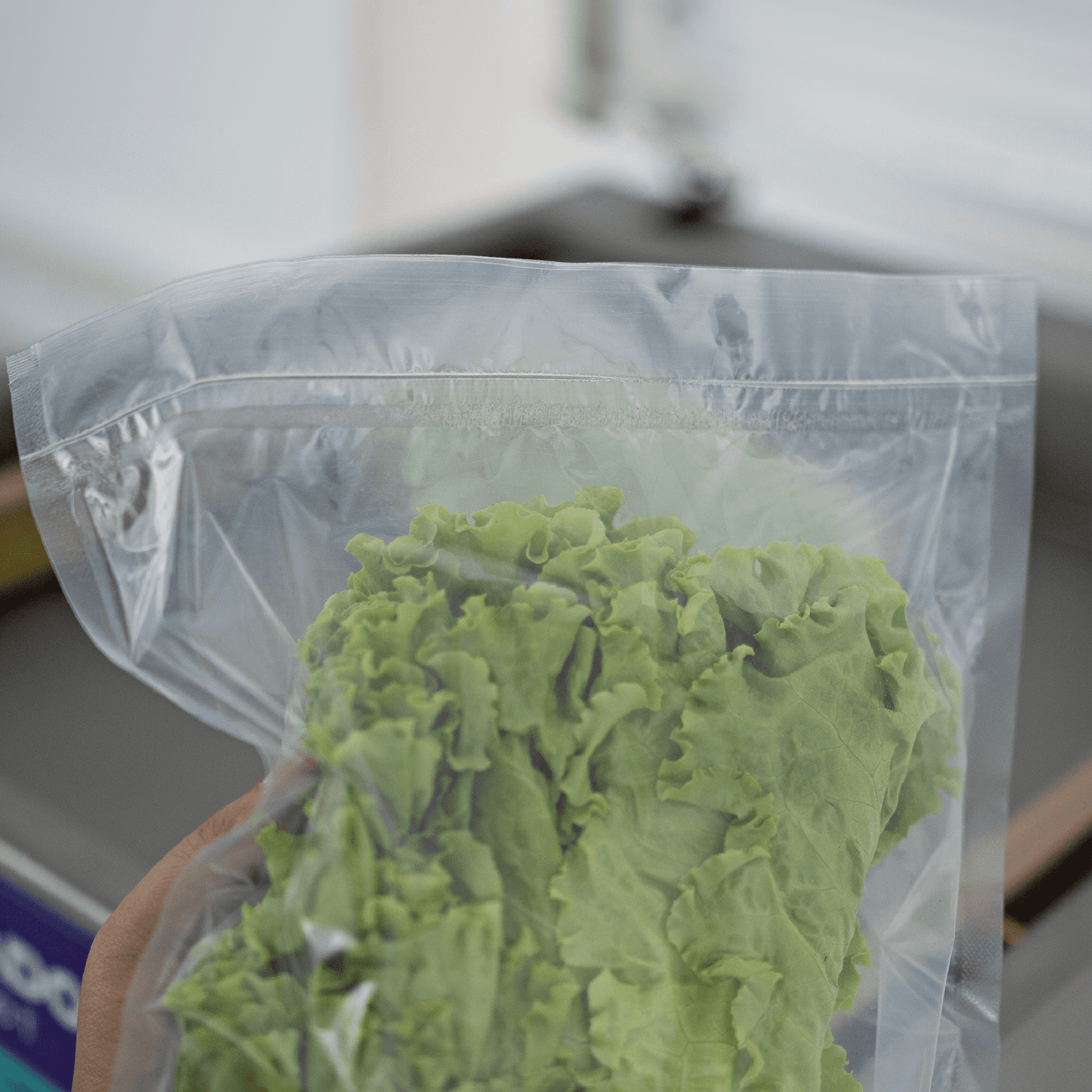

Various segments of industry and commerce use Cetro CCVS 500 T to seal packages with meat, snacks, fish, vegetables, cereals, sausages, pizza, the hearts of palm, sliced cold cuts, poultry, pasta, cheese, beef, frozen foods, mushrooms, fruits, and others.

Vacuum packaging improves product presentation and appearance, facilitates display in your sales area, reduces storage space, and eliminates the risk of contamination from handling, among other benefits.

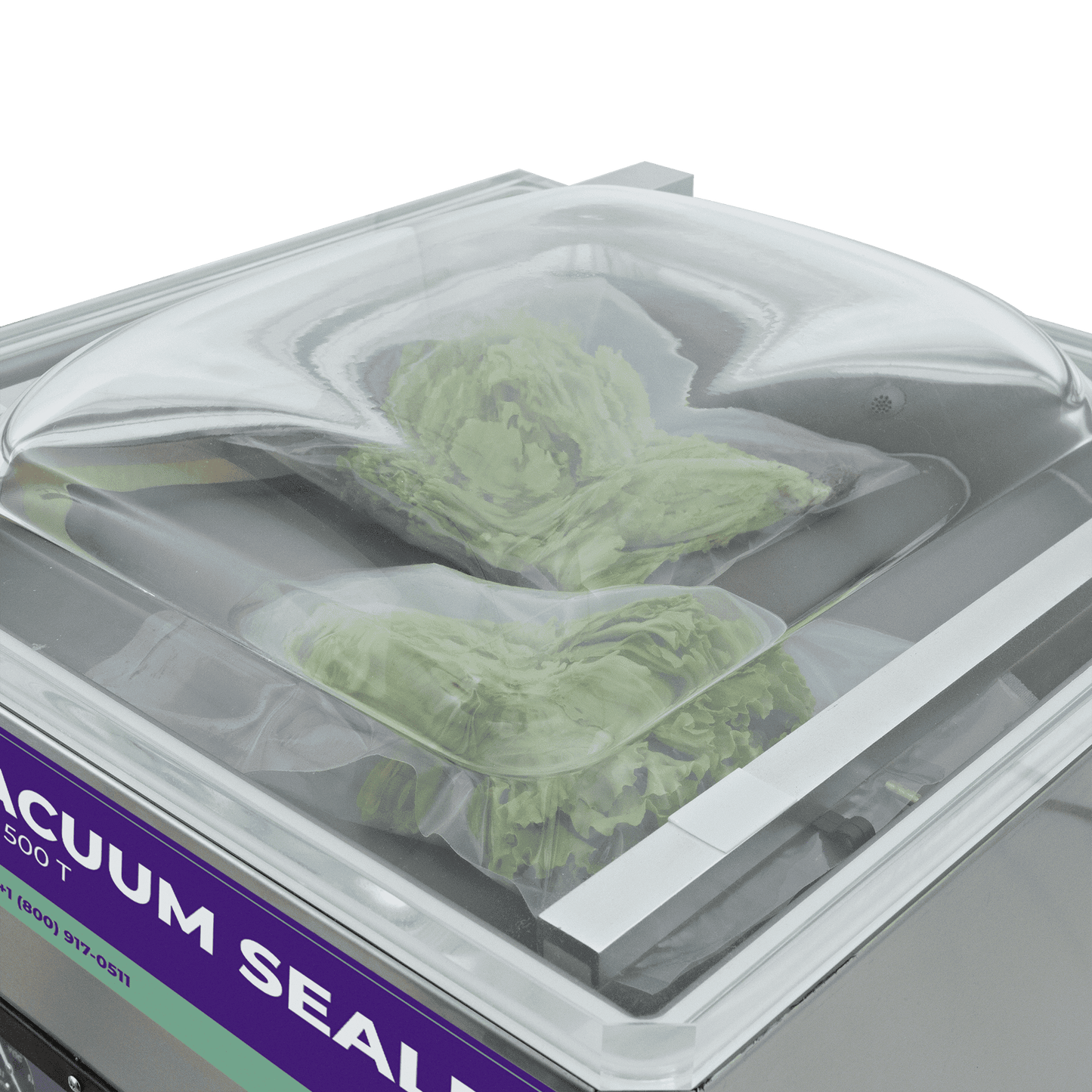

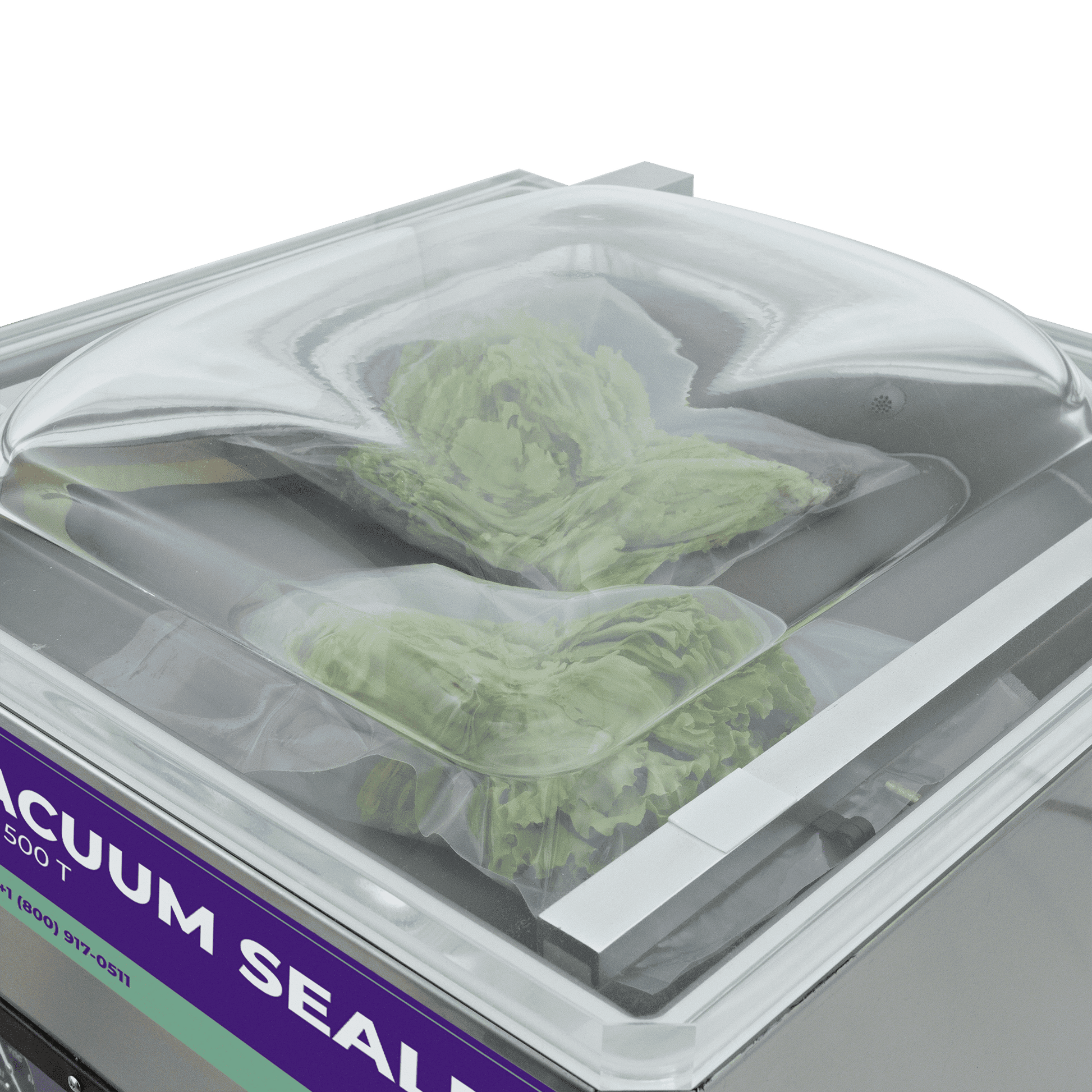

ADVANTAGES OF MAP

MAP (Modified Atmosphere Packaging) is one of the most utilized packaging technologies in the processing and storage of fragile products in general, such as snacks, salads, potato chips, and other food products, without the risk of damaging the food.

MAP is the injection of a gas atmosphere, typically containing an inert gas, such as nitrogen combined with carbon dioxide, into a packaged food product to extend its shelf life.

Carbon dioxide is effective at inhibiting microorganisms, such as mold and other bacteria common in the air, reducing the pH value inside the package. Nitrogen is an inert gas used primarily to eliminate air from the inside of the package and prevent oxidation. It also maintains the internal volume of the package, preventing the products from crushing.

Need Help?

Click here to speak to a sales representative now or call +1 (800) 917-0511 and ask all your questions.

Easy Payment

Easy Payment Consulting with Experts

Consulting with Experts Secure Purchase

Secure Purchase