Technical Sheet

| Model

|

CASM 1000 SS

|

| Energy Consumption |

0.5 kW

|

| Standard Power

|

600 W

|

| Conveyor Speed | 0-13 m/min

|

| Sealing Width |

0.39 inches |

| Plastic Thickness |

0.00079 - 0,0031 inches

|

| Temperature

|

0-300 ºC

|

| Load Capacity |

5 kg

|

| Printing

|

2 lines, 40 characters

|

| Structure Material

|

201 Stainless Steel

|

| Horizontal Dimensions (L x W x H)

|

36 x 15-17 x 12 inches |

| Vertical Dimensions (L x W x H) |

36 x 15 x 18-24 inches |

| Weight

|

28,4 kg

|

About the product

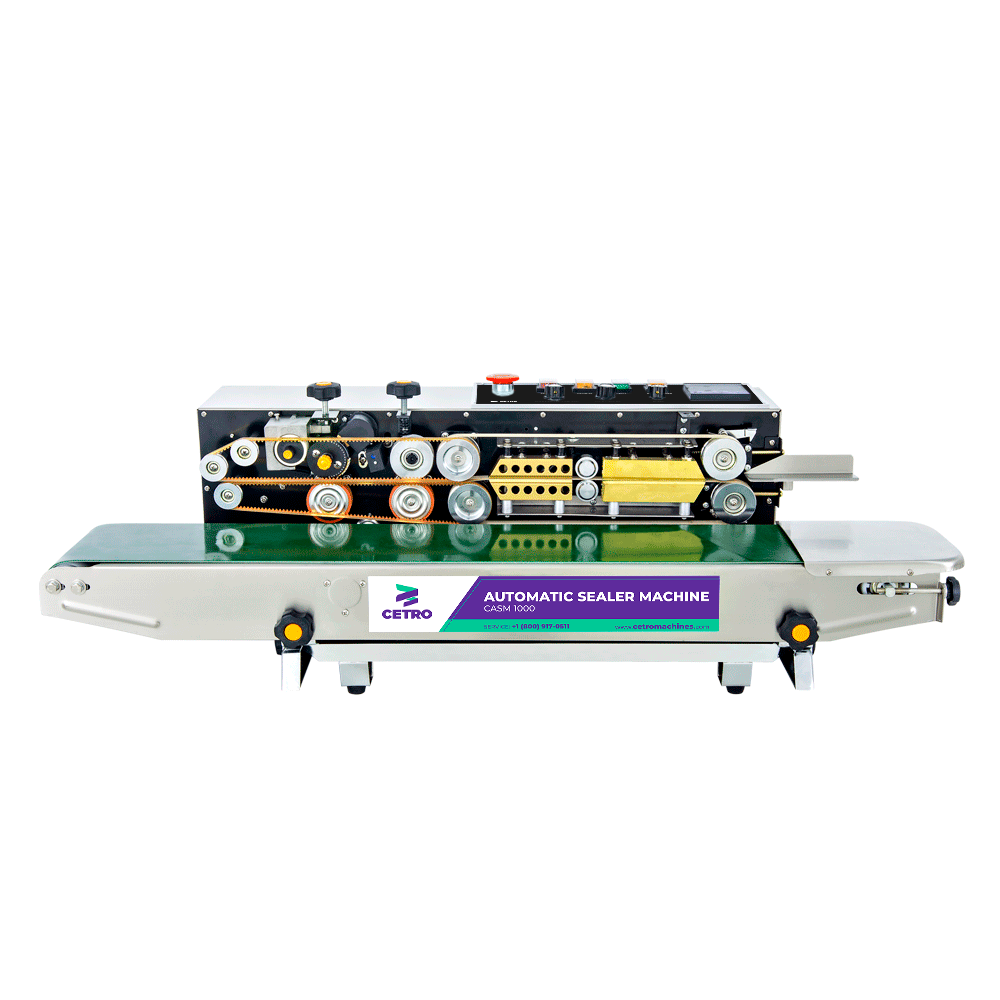

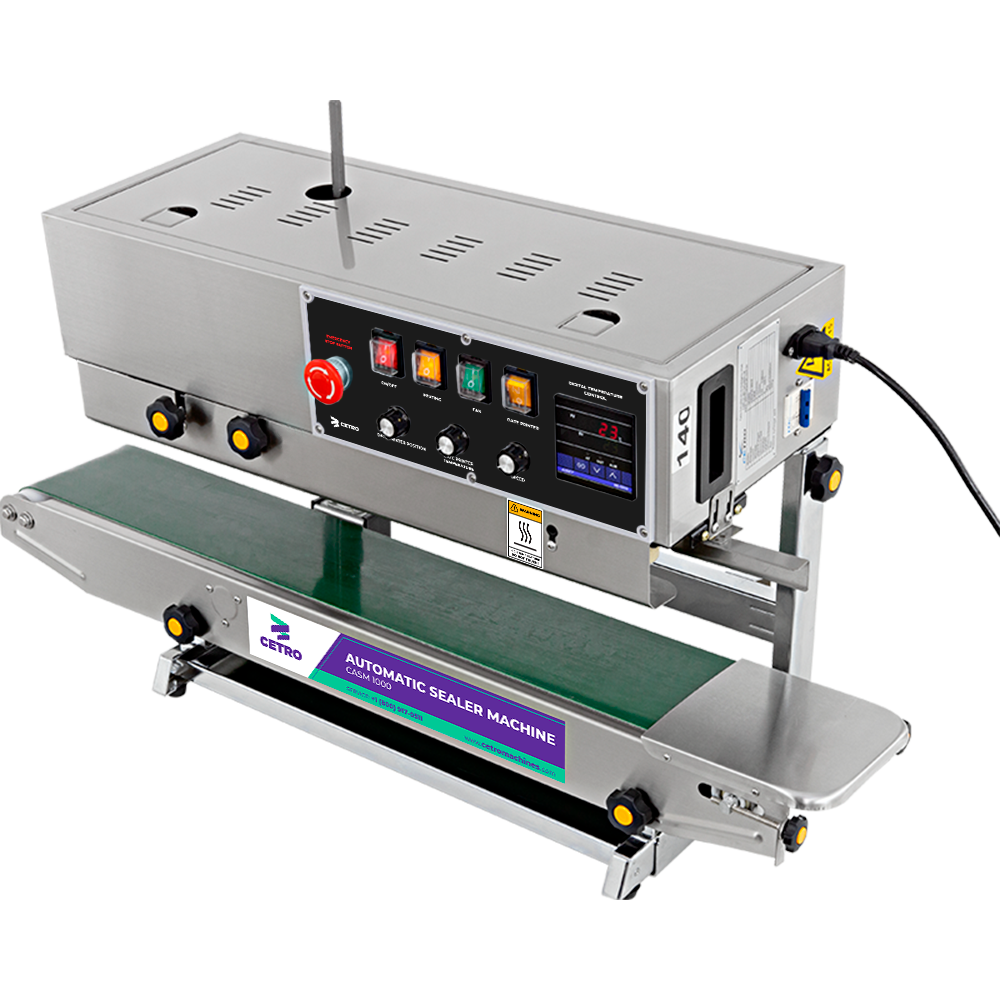

Cetro Automatic Sealer Machine CASM 1000 SS

This model can speed up production and reduce labor costs. Its conveyor makes the operation continuous to optimize it. The equipment can seal approximately 19,200 packages a day; its operation can be set easily and intuitively to ensure uniform and tamper-proof sealing.

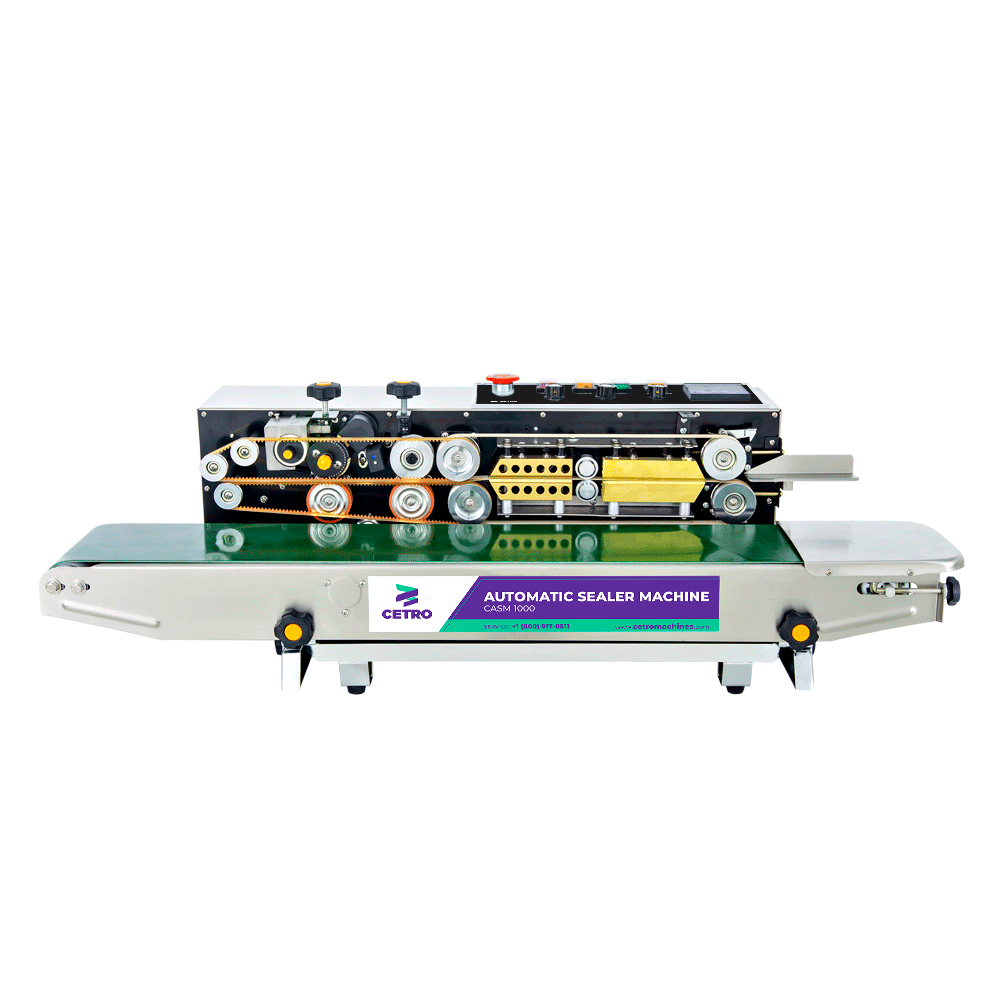

HORIZONTAL AND VERTICAL SEALINGS

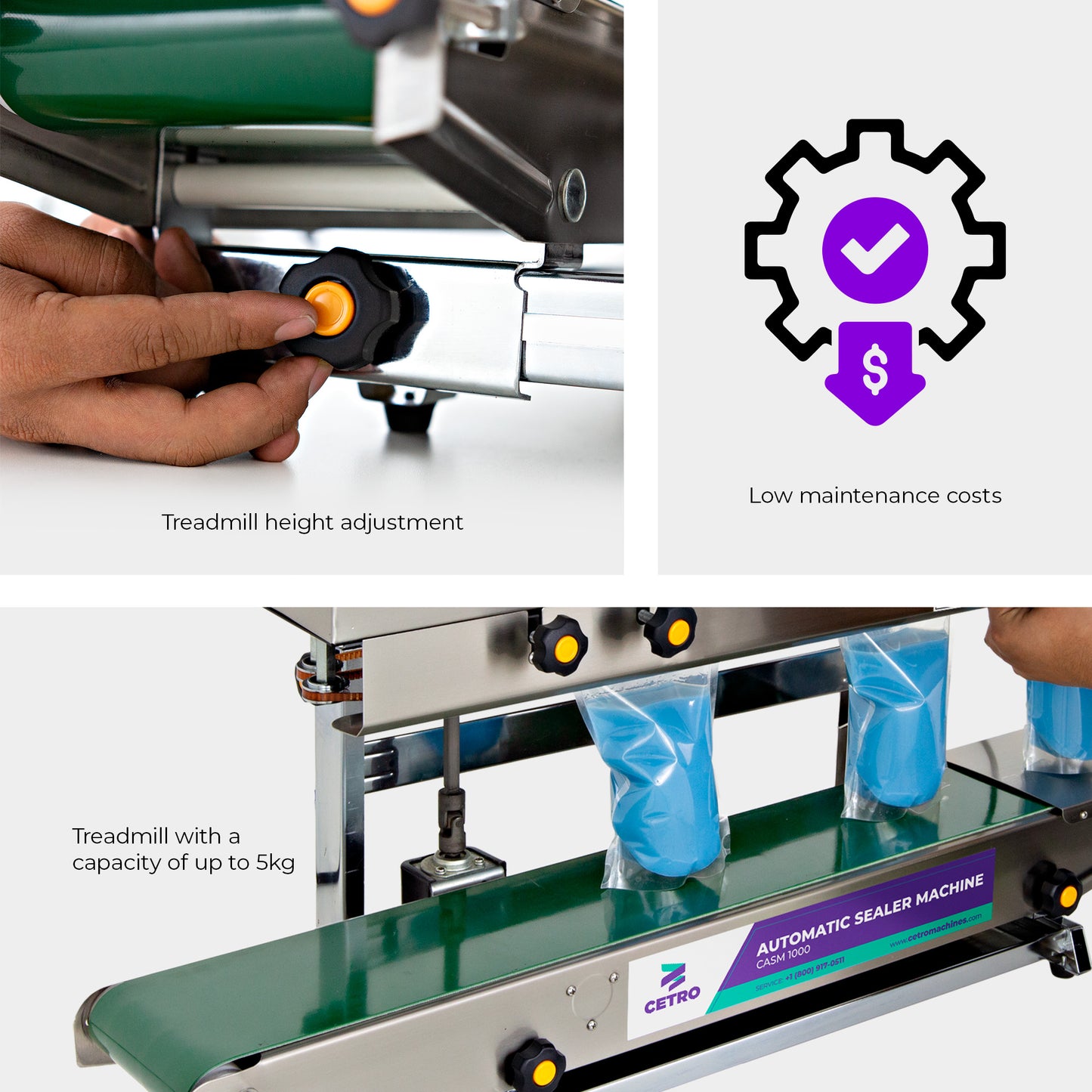

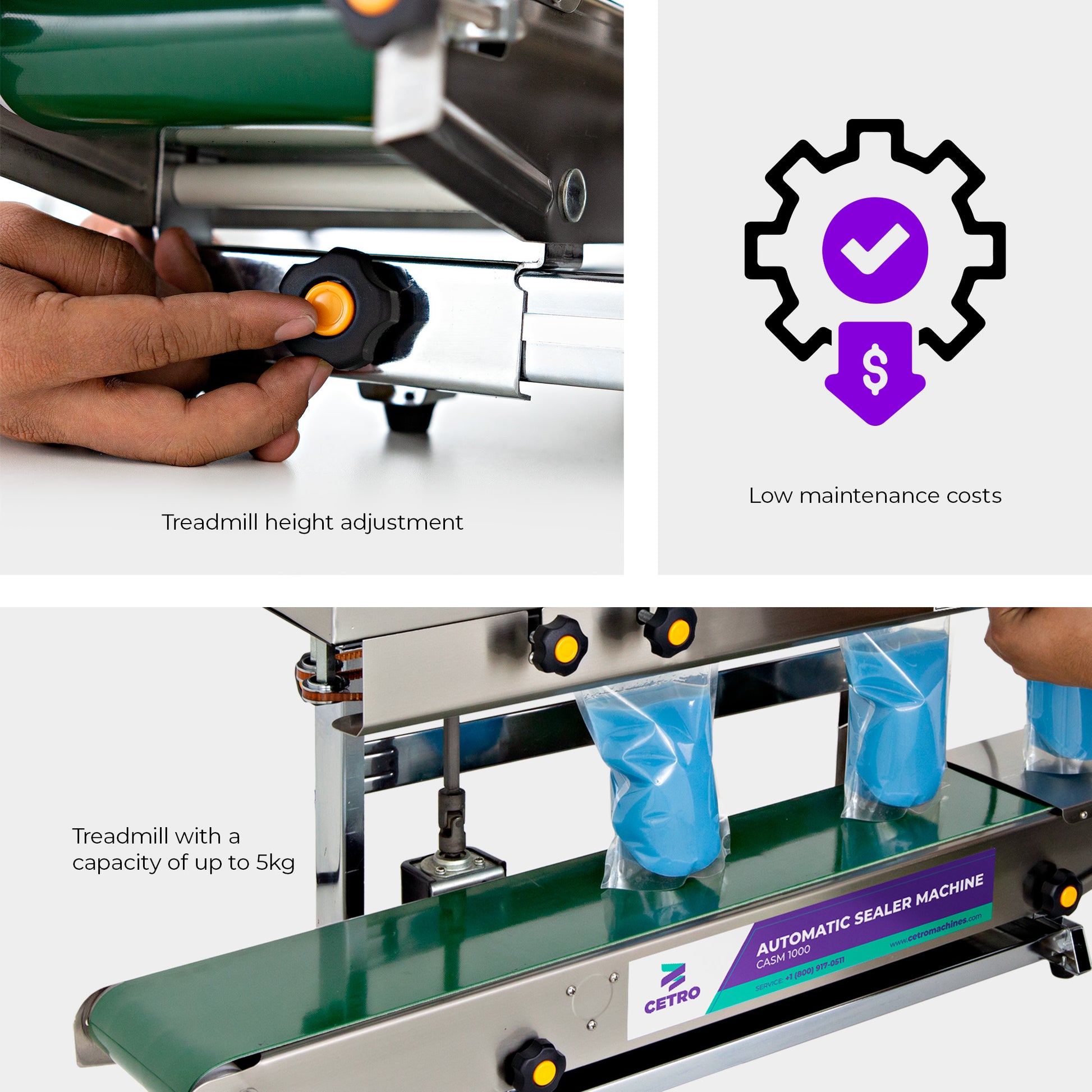

The horizontal sealing operation is suitable for dry foods like grains, peanuts, and spices. On the other hand, the vertical sealing operation is ideal for larger goods or those holding liquids, providing additional security throughout the procedure.

This model has height adjustments between 3,9 and 14 inches when used vertically, and its conveyor has a load capacity of 5 kg, making CASM 1000 SS an excellent option for different production sectors.

SIMPLE AND INTUITIVE PANEL

The machine’s panel is easy to set up. The sealing temperature can be adjusted based on the kind and thickness of the packing, the conveyor speed, and the date printer's temperature.

APPLICATION

Cetro Sealer Machine has a Teflon thermal insulation that keeps the resistor from touching the packaging; thus, the machine can seal bag toppers and header cards (for spices, condiments, honey, and more), PE, PP, BOPP, and PET materials, stand-up bags, and other types of packaging.

SEALING DETAILS

With a sealing 0,39 inches wide and a temperature reaching up to 300 ºC, this machine performs an extremely safe sealing, sealing even liquid products such as sauces and preserves. To seal bag toppers, increase the temperature to approximately 280 ºC and decrease the speed.

DATE PRINTER

The Date Printer works by hot stamping, printing 2 lines and 40 characters. The letters and digits are heated with ink to print the information on the packaging, such as the manufacturing date, expiration date, and batch number.

This process is extremely tamper-proof, thus, the packaging can be stored in environments with temperature changes, such as freezers, cold rooms, and display cases. The printing system is economical, reaching up to 100 thousand bags.

STAINLESS STEEL

Its 201 stainless steel structure is easy to clean and highly resistant to corrosion and oxidation. This material offers more quality and durability to the machine, making the Sealer suitable for any work environment that needs hygienic and safe processes.

Need Help?

Click here to speak to a sales representative now or call +1 (800) 917-0511 and ask all your questions.

Easy Payment

Easy Payment Consulting with Experts

Consulting with Experts Secure Purchase

Secure Purchase